- Contact Us

- |

- Jobs

- |

- About Us

- |

- |

-

- Personal information

- Organization

- Quotes

- Address book

- Login

- Don't have an account? Sign-up

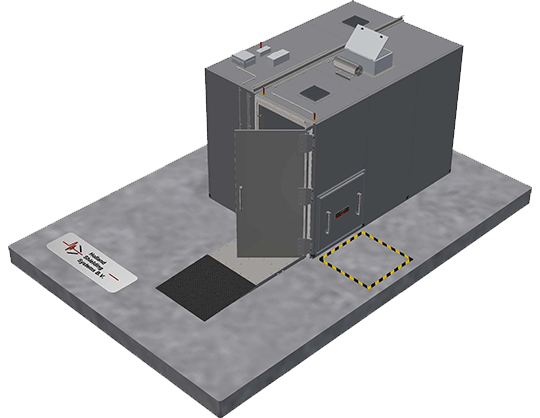

Prefabricated and modular faraday cages

- Home

- EMP - EMI shielded racks

- Prefabricated and modular faraday cages

A freestanding (independent of the host building) prefabricated modular Faraday cage provides a superior screening from RF/LF/HF-signals and is applicable in a wide range of situations for a wide range of purposes.

The modular Faraday cage is designed to meet or even exceed the vast majority of shielding requirements requested in today's society.

Applications

- LF/RF/HF tests

- EMC test labs

- Wireless product testing

- EMI/RFI shielded server rooms

- Protection of sensitive information (NATO TEMPEST standards)

- HEMP & EMP protection

- SCIF (Sensitive Compartmented Information Facility)

- Neuroscience laboratories

- Cellular communication devices

- Immunity & emission test chambers

- Anechoic chambers

- Neurology labs

Advantages

- Freestanding construction

- High shielding performance without deterioration

- Easy to modify, enlarge or reinstall with conventional hand power tools

- Optionally supplied as a kit for assembly by the user

- Easy to mount by skilled local workers

- Many sizes directly available from stock, custom designs available within a few weeks

- Standard 10 years warranty, moving parts and electronics excluded.

Options

Examples of several options are listed below:

- (Customized) shielded honeycomb ventilation panels

- Shielded doors

- Automatic sliding doors

- Double leaf door

- Double door as in sluice-gate construction

- Bolts on the in- or outside for construction convenience

- Shielded piping for water or gas flow

- Acoustic panels on the inside

- Lightweight version

- Entry panel fitted with:

- Power filters, single- or three phase +N (specify amperage, voltage and frequency)

- Feed through signal filters

- Wave guides for passage of fiber-optic cables

- Feed through penetration (e.g. SMA- or BNC connector)

- Grounding bolt

Shielding performance

Shielding performance graph of a standard prefabricated cage vs a high performance Faraday cage

Prefabricated Faraday cage [Magnetic]

Please note : These values are measured under laboratory conditions. Results may vary in other situations; please read our Guarantee.

Prefabricated Faraday cage [Electric]

Dimensions

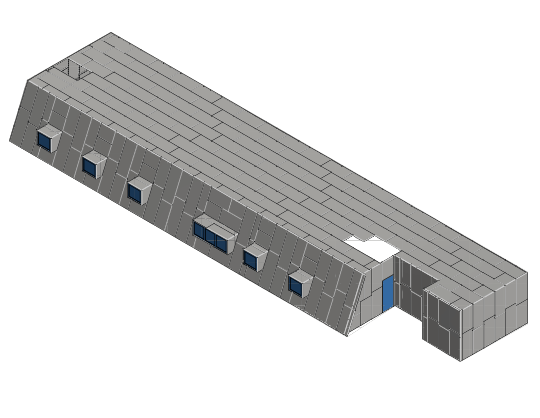

Our prefabricated Faraday cages can be made in almost any size. By default, the following prefabricated Faraday cage panels are in stock and can be delivered quickly. A Faraday cage can also be produced according to the customers specifications. At any moment you can make it bigger or smaller and even create different shapes.

Standard cage dimensions

| Length (mm) | Width (mm) | Height (mm) |

|---|---|---|

| 1090 | 1170 | 2315 / 2840 / 3405 |

| 1090 | 2260 | 2315 / 2840 / 3405 |

| 2180 | 2260 | 2315 / 2840 / 3405 |

| 3270 | 2260 | 2315 / 2840 / 3405 |

| 3270 | 3350 | 2315 / 2840 / 3405 |

| 4360 | 2260 | 2315 / 2840 / 3405 |

| 4360 | 4440 | 2315 / 2840 / 3405 |

| 5450 | 5530 | 2315 / 2840 / 3405 |

| Custom sizes | ||

If a prefabricated Faraday cage is too small, one can increase the size by adding additional panels to the Prefabricated Faraday cage later.

Additional product information and material use

The prefabricated Faraday cage consists of galvanized (2 mm thick) Mu-Ferro steel shielding panels. The galvanization ensures excellent resistance to corrosion.

Gaskets are applied between all panels of the Faraday cage to ensure a good electrical conductivity and a good seal between the panels. The gaskets are produced in our gasket production facility.

To ensure a high shielding performance over time, the bare modular prefabricated Faraday cage construction does not contain any wooden parts that could be affected by variations in temperature or moisture.

In short, the corrosion resistant panels guarantee excellent electrical conductivity and provide a high shielding effectiveness.

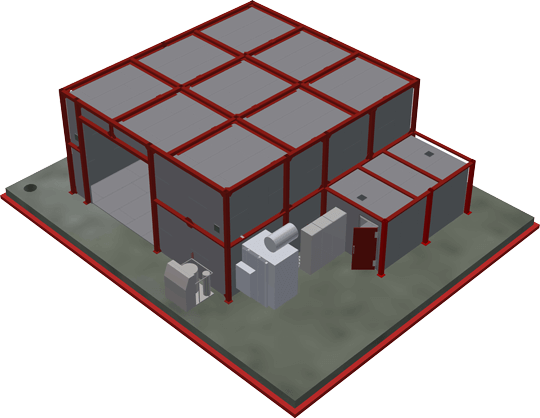

Fully finished interior

We can also provide a fully finished interior. The walls and ceiling of the cage can be completely decorated with wood, and the floor with carpeting so that the shielding panels of the cage are no longer visible.

Below is an example of a prefabricated Faraday cage before and after its interior finish.

Air conditioning, lighting, wall outlets, cable ducts, work tables and many more features can be taken into account in this complete interior finish.

In house production facility

We produce Faraday cages daily and are therefore able to quickly deliver standard sizes from our large stock.

The panels we keep in stock can also be adjusted quickly according to your needs, for example for the input of power line filters, waveguides, honeycomb ventilation panels, etc. These custom sizes can be produced in several weeks from order date. When desired, the Faraday cage can also be adjusted on location.

We can deliver a cage in any requested size with any requested attenuation. If a straightforward cage with low attenuation requirements is desired, we can deliver the cage standard from stock for an attractive price.

The modular panels can be shipped and assembled by the customer or under supervision of our engineers, anywhere in the world.

How to order

For a quotation of a prefabricated Faraday cage please send an email with drawings of the room that requires shielding.

In case no drawings of the room are available, we must know the amount of square meters that require shielding.

Also indicate the application of the shielded room. This enables us to think about the right solution from scratch.