- Contact Us

- |

- Jobs

- |

- About Us

- |

- |

-

- Personal information

- Organization

- Quotes

- Address book

- Login

- Don't have an account? Sign-up

Mesh Foil for window shielding

- Home

- EMC windows, EMI displays & conductive transparent sheets

- Mesh Foil for window shielding

Mesh foil is a very fine, electrically conductive wire mesh laminated between two layers of scratch-resistant transparent foil. The wires are so fine that they can hardly be seen with the naked eye. The product is very strong but it still bends easily. It is easy to apply Mesh foil onto glass, acrylic and polycarbonate, either by hand or with a laminator. It can be supplied with or without self-adhesive.

The foil can be made with flying mesh on the sides or around the foil. This means that a part of the very fine wire mesh is not covered in transparent foil. The exposed edges of wire mesh can be used to create an electrical connection with your enclosure. Alternatively a conductive or non-conductive adhesive can be provided along the edges or there can be a silver busbar around the circumference.

Maximum sheet/roll width approx 1035 mm.

Turnkey windows

If you are interested in ready-made mesh-foil windows, please take a look at our EMI/RFI shielded mesh foil windows. Here the mesh foil is bonded between two layers of glass or plastic, or a single layer of mesh foil is fixed onto one side of a single glass or plastic window.

Technical details

| Type (wires/inch) | 130 |

|---|---|

| Mesh total thickness (mm) | 0.085 ±0.01 |

| Nominal aperture (mm) | 0.110 |

| Light transmission % | 64.5 |

Shielding performance in graph

Mesh foil applications

Shielding displays, windows, touch screens, monitors, LCD screens, TEMPEST.

Options (on request)

- Stainless steel wire mesh

- Blackened copper wire mesh

Mesh foil options

High performance foil for windows & displays:

- No adhesive 9000 serie

- Transparent adhesive 9100 serie

- Scratch resistance 9200 serie

- Scratch resistance adhesive 9300

- Micro suction silicone adhesive 91SUC

Micro suction silicone adhesive

For easy manual application of the foil we have developed a new Micro Suction Silicone adhesive. This adhesive has a number of advantages that make the film easy to position. Our advise is to use standard adhesive only for laminating machines or very very experienced people. For all else use this Micro Suction Silicone Adhesive

Benefits

- Reusable / Repositionable

- Never attach permanently

- Easy to apply by hand, less bubbly

Please note : Mesh foil with Micro Suction Silicone adhesive has a thickness of 450 micron / 0.45 mm.

Please note: the top layer can be affected by acids, for example from human skin. To protect the conductive layer, you can apply a transparent film or you can have the adhesive side facing out. Max. working temperature 60 ºC.

Small optical defects are expected to occur with this product. If you require a product that has absolutely no optical defects, please contact us for the "superior selected quality". Do please realize that due to the extreme care needed to manufacture these products, they can be several times more expensive.

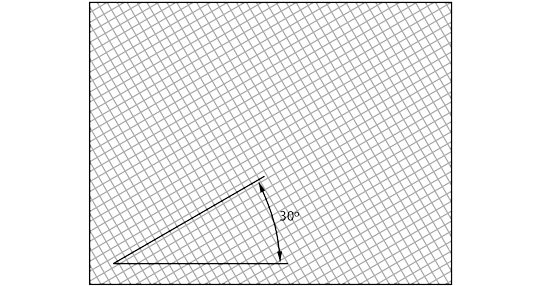

Wire-mesh angle

Mesh foil with moiré effect and without moiré effect

- The wire mesh can be placed at a custom angle to prevent the moiré effect on your display (standard is 0 degrees).

- A custom wire-mesh angle is only available with sheet styles 1 and 5

NOTE: For LCD displays, 17°, 35° or 45° are used typically. We recommend that you request a sample of the product to determine the proper angle of the wire mesh for your application.

Mesh foil sheet styles

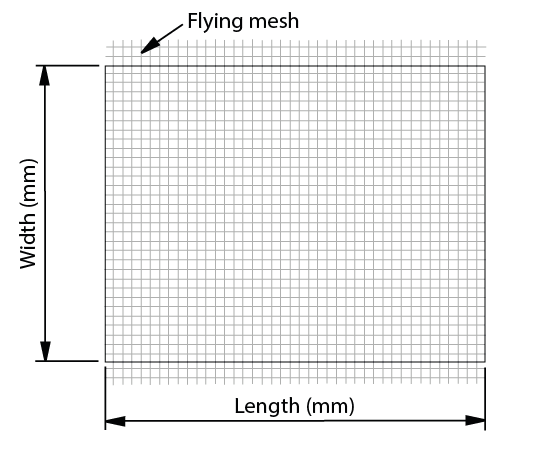

Mesh foil with or without flying mesh

#1STD Standard mesh foil (sheet style 1)

Mesh foil laminated between two layers of plastic. Available with or without a transparent self-adhesive layer.

#2FTB Flying mesh at top and bottom (sheet style 2)

Mesh foil with flying mesh, laminated between two layers of plastic. At the top and the bottom of the mesh foil there is an exposed strip of wire mesh to make a connection with your enclosure.

#3FAR Flying mesh on all sides (sheet style 3)

Mesh foil with a 3-4mm flying mesh all around, laminated between two layers of plastic. Around the mesh foil there is an exposed strip of wire mesh to make a connection with your enclosure.

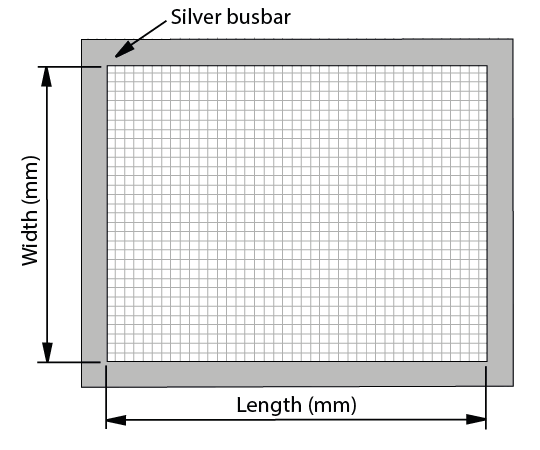

Mesh foil with a silver busbar

#4BTB Silver bar at top and bottom (sheet style 4)

Mesh foil with 3-4 mm silver busbar, laminated between two layers of plastic.

At the top and the bottom of the mesh foil there is a silver strip (busbar) to make a perfect electrical connection with your enclosure.

#5BAR Silver bar on all sides (sheet style 5)

Mesh foil with a 3-4 mm flying mesh, laminated between two layers of plastic. On all sides of the mesh foil there is a silver strip (busbar) to make a perfect electrical connection with your enclosure.

Mesh foil mounting examples

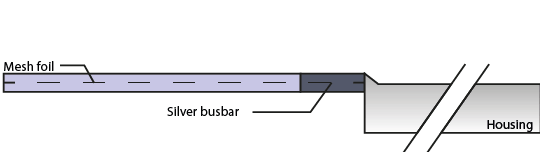

Mounting example 1

Mesh foil mounted with Conductive glue 3980 series

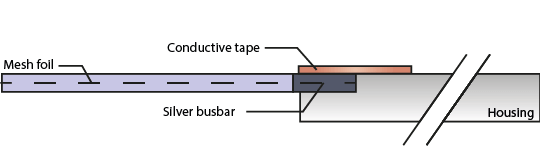

Mounting example 2

Mesh foil mounted with Conductive tape 3201

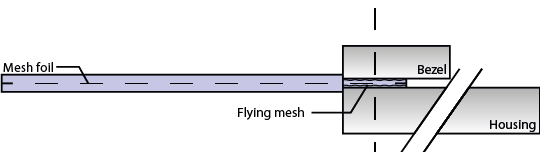

Mounting example 3

Mesh foil mounted in a clamping construction

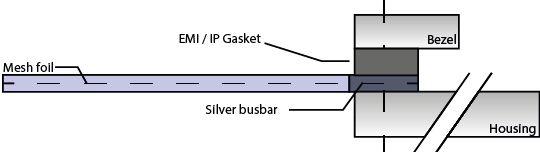

Mounting example 4

Standard Mesh foil mounted in a clamping construction with an EMI gasket. A water seal is possible here.