- Contact Us

- |

- Jobs

- |

- About Us

- |

- |

-

- Personal information

- Organization

- Quotes

- Address book

- Login

- Don't have an account? Sign-up

EMI/RFI shielded mesh foil windows

- Home

- EMC windows, EMI displays & conductive transparent sheets

- EMI/RFI shielded mesh foil windows

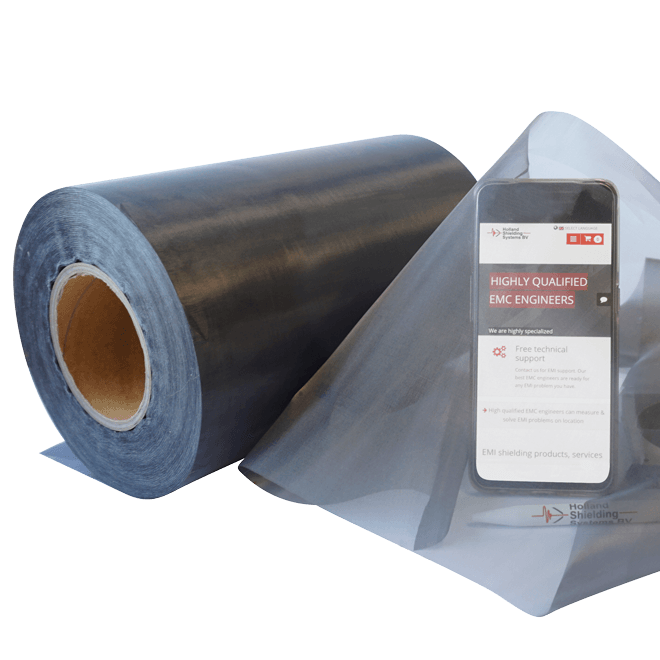

For the highest possible EMI / RFI shielding performance, a woven electrically conductive microstructure of mesh is bonded between two layers of glass or plastic (stepped double layered window). The EVA combined with the mesh will work as reinforcement for the glass. Alternatively, a single layer of EMI/RFI shielded mesh foil windows is fixed onto one side of a single glass or plastic window with self-adhesive (single layered window).

This can be done by laminating or edge bonding. The EMI-shielded mesh-foil windows can be provided with a silver bus bar, an electrically conductive gasket or can be supplied with a frame for easy mounting. Windows can optionally be provided with a water seal.

Window types

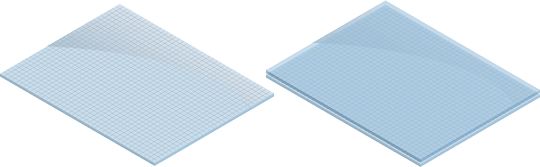

|

|

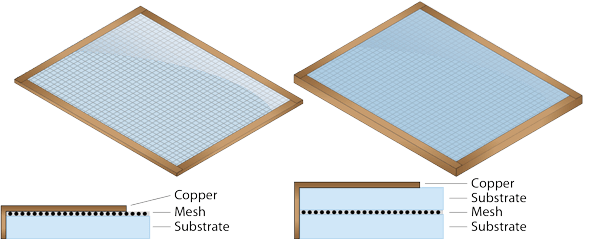

| Single layer: Wire mesh fixed onto one side of glass or plastic substrate. |

Double layer: Wire mesh fixed between two layers of glass or plastic substrate. |

| Note that it is also possible to laminate the wire mesh under a custom angle to prevent moiré effect on for example monitors or LCD displays. |

|

|---|---|

Technical details

| Material | Conductive mesh flash nickel (black) (standard) |

Conductive mesh flash nickel | Conductive mesh stainless steel |

|---|---|---|---|

| wires/inch (OPI) | 130 | 130 | 100 |

| Mesh total thickness (mm) | 0.085 ±0.01 | 0.085 ±0.01 | 0.050 ±0.01 |

| Nominal Aaperture (mm) | 0.110 | 0.110 | 0.204 |

| Light Transmission % | 64.5 | 64.5 | 64.5 |

Please note: top layer can be affected by acid for example from the human skin. To protect the conductive layer, you can apply a transparent film or use the adhesive side on top. Max. working temperature 60 ºC.

Small optical defects are allowed in this product. If you require a product that has absolutely no optical defect then contact us for the "superior selected quality". Please realize that by the extreme caution taken in production, these products can be several times more expensive.

Light transmission

Opacity of mesh windows is 64.5%. A lack of available light should not be a concern, since an average pair of sunglasses allows less than 9% light to come through.

Applications

- LCD displays

- Membrane switches

- Touch screens

- Defense / Avionics etc.

- Devices for medical technology

- For test and measuring instruments

Window materials

EMI/RFI shielded mesh foil windows can be made from your existing windows or can be supplied as a new window made of:

- Polycarbonate (material code P)

- Acrylic (material code A)

- Glass (material code G)

- Polycarbonate scratch resistant (material code PS)

Shielding performance

Please note : These values are measured under laboratory conditions. Results may vary in other situations; please read our Guarantee.

Contact edges

|

|

| CO : Copper busbar (Single layer) Wire mesh fixed onto one side of glass or plastic substrate. |

CO : Copper busbar (Double layer) Wire mesh fixed between two layers of glass or plastic substrate. |

|

|

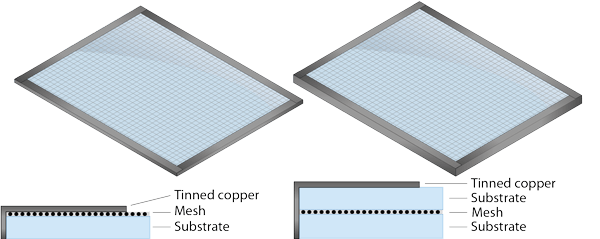

| TC : Tinned copper busbar (Single layer) Wire mesh fixed onto one side of a glass or plastic substrate. With tinned copper edges for easy soldering and grounding. |

TC : Tinned copper busbar (Double layer) Wire mesh fixed between two glass or plastic substrate. With tinned copper edges for easy soldering and grounding. |

|

|

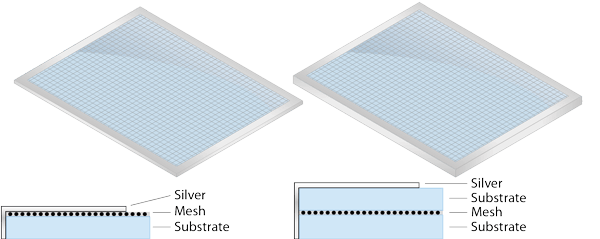

| SB : Silver busbar (Single layer) Wire mesh fixed onto one side of glass or plastic substrate. | SB : Silver busbar (Double layer) Wire mesh fixed between two layers of glass or plastic substrate. |

|

|

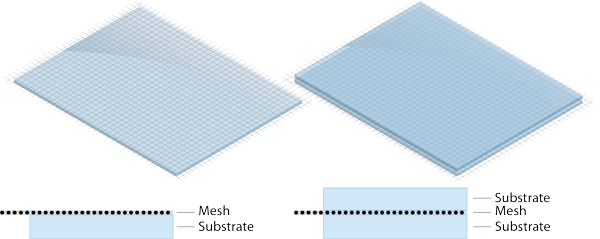

| FM : Flying mesh (Single layer) Wire mesh fixed onto one side of glass or plastic substrate. |

FM : Flying mesh (Double layer) Wire mesh fixed between two layers of glass or plastic substrate. |

|

|

|

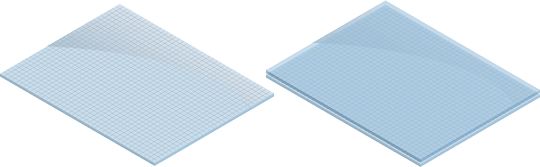

NO : No contact edge (Single layer) |

NO : No contact edge (Double layer) Wire mesh fixed between two layers of glass or plastic substrate. |