- Contact Us

- |

- Jobs

- |

- About Us

- |

- |

-

- Personal information

- Organization

- Quotes

- Address book

- Login

- Don't have an account? Sign-up

High temperature resistant EMI gasket

- Home

- EMI shielding gaskets solutions

- EMI shielding gaskets

- High temperature resistant EMI gasket

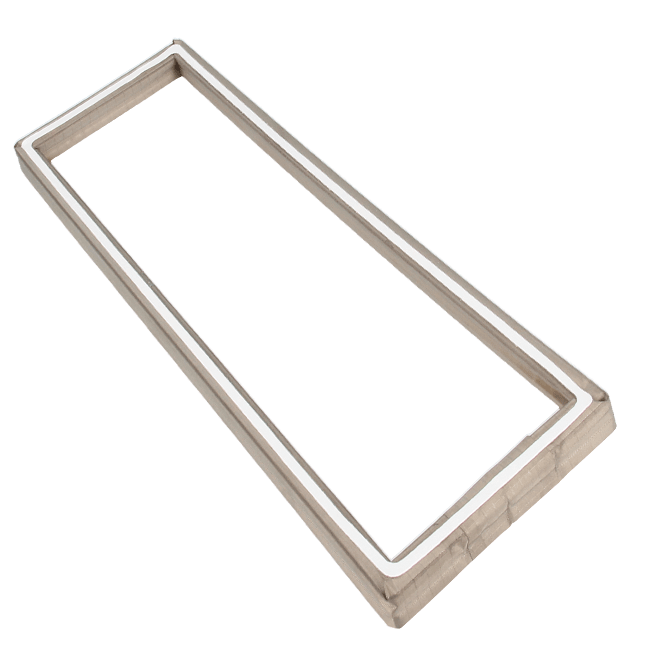

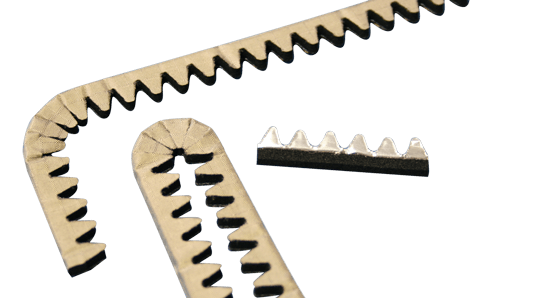

The 7100 High temperature resistant EMI gasket series is a HF shielding gasket with high shielding performance and extremely low closure force. This prevents deflection of doors/parts, which improves shielding effectiveness. The 7100 is very effective in combination with stainless steel and metals. The core consists of a high-grade FUBA foam which is an EPDM foam covered with high conductive wear & tear resistant metallized fabric. This EMI gasket is used in large scale in automotive production up to 135 °C.

FUBA foam general description

FUBA foam is a semi-closed cell EPDM foam with excellent sealing properties. The semi-closed cell structure combines the flexibility of open cell types with the excellent sealing capabilities of closed cell types (after compression). This unique foam can be laminated with advanced adhesive technology to seal (complex) gaps against water, wind, dust, noise and heat.

FUBA foam characteristics

Good resistance to UV, humidity, high and low temperatures and chemicals (such as acids and alkalis). The flexibility of the foam makes sure that the optimal sealing performance is obtained, even with expansion or contraction of the structure caused by temperature changes. Thanks to the low compression load the foam will never deform the structure after application.

Combined with advanced adhesive technology, the foam can be applied on greasy, rough, smooth and low energy surfaces. No heavy metals (such as cadmium) or regulated substances (such as CFC’s and halogen gases) are used during the manufacturing process nor in the product itself. FUBA foam can be disposed of by incineration.

Application

FUBA foam gaskets are specifically designed to seal (complex) gaps against electrical noise and heat. Depending on the applications, the EMI gasket needs to be compressed between 50-80% to activate its sealing properties. Automotive - sealing of HVAC unit, dashboard, air duct, glass run, fire wall. Building and construction - sealing of exterior panel joints, solar panels. Industrial - sealing of air-conditioners, mobile phones, refrigerators.

Please note : These values are measured under laboratory conditions. Results may vary in other situations; please read our Guarantee.

Features

- Semi-closed cell structure

- Good UV resistance

- Good weatherability

- Low compression load

- Very high electrical conductivity

- High shielding performance

- Roll length of 1 to 1000 meters.

(Depending on width and height of the EMI gasket) - Easy to fit with self-adhesive

- High abrasion resistance

- Can be cut with scissors

- Because the FUBA foam series is so soft, it is easy to bend around corners

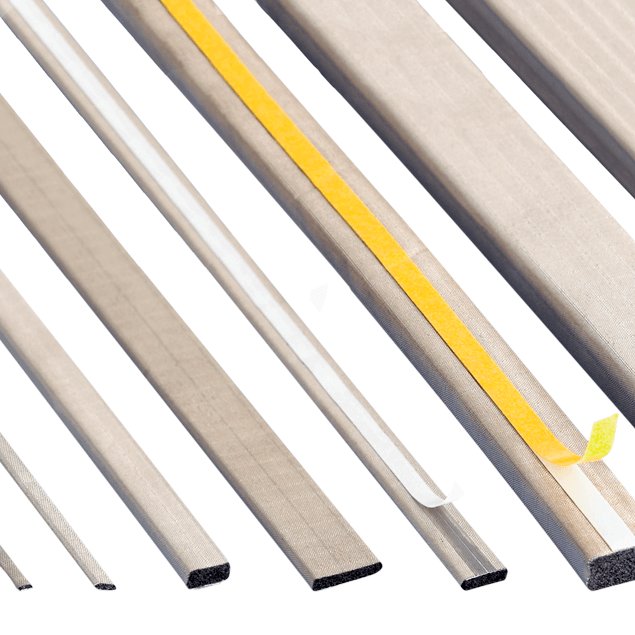

Tape specification

- With standard self-adhesive placed in the middle

- Without self-adhesive

- With conductive self-adhesive

- Standard self-adhesive, asymmetrical

- Standard self-adhesive placed on the side

FUBA foam core specifications

| Properties | Value | Standard |

|---|---|---|

| Density | 95 kg/m³ | ISO 845 |

| Thickness | 3-30 mm | |

| Temperature - service (continuous) | -40 to 135 °C | |

| Compression load (50%) | 5 kPa | ISO 844 |

| Elongation | 430 % | ISO 1798 |

| Elongation - acid (1% H2SO4) | 430 % | immersion at 20 °C for 7 days |

| Elongation - alkaline (1% NaOH) | 390 % | immersion at 20 °C for 7 days |

| Elongation - initial | 430 % | immersion at 20 °C for 7 days |

| Tensile strength - acid (1% H2SO4) | 81 kPa | immersion at 20 °C for 7 days |

| Tensile strength | 90 kPa | ISO 1798 |

| Tensile strength - alkaline (1% NaOH) | 77 kPa | immersion at 20°C for 7 days |

| Tensile strength - initial | 90 kPa | immersion at 20°C for 7 days |

| Water absorption | ISO 2896 | |

| Flammability | pass | FMVSS 302 |

| Weatherability | excellent | |

| High deflection | up to 65 % |

it is possible to cut out small bites in positions you specify so that the gasket becomes easy to bend. It is also possible to cut out squares or circles for easy mounting or positioning during assembly.

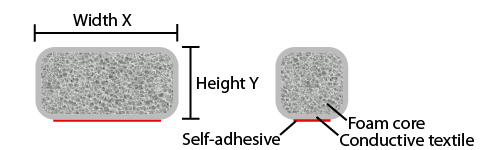

Standard dimensions

| Width X (mm) | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| 4 | 5 | 6 | 9 | 10 | 12 | 15 | 18 | 20 | 25 | ||

| Height Y (mm) | 3 | 7100-4-3 | 7100-5-3 | 7100-6-3 | 7100-9-3 | 7100-10-3 | 7100-12-3 | 7100-15-3 | 7100-18-3 | 7100-20-3 | 7100-25-3 |

| 4 | 7100-4-4 | 7100-5-4 | 7100-6-4 | 7100-9-4 | 7100-10-4 | 7100-12-4 | 7100-15-4 | 7100-18-4 | 7100-20-4 | 7100-25-4 | |

| 6 | 7100-6-6 | 7100-9-6 | 7100-10-6 | 7100-12-6 | 7100-15-6 | 7100-18-6 | 7100-20-6 | 7100-25-6 | |||

| 8 | 7100-9-8 | 7100-10-8 | 7100-12-8 | 7100-15-8 | 7100-18-8 | 7100-20-8 | 7100-25-8 | ||||

| 9 | 7100-9-9 | 7100-10-9 | 7100-12-9 | 7100-15-9 | 7100-18-9 | 7100-20-9 | 7100-25-9 | ||||

| 10 | 7100-10-10 | 7100-12-10 | 7100-15-10 | 7100-18-10 | 7100-20-10 | 7100-25-10 | |||||

| 12 | 7100-12-12 | 7100-15-12 | 7100-18-12 | 7100-20-12 | 7100-25-12 | ||||||

| 15 | 7100-15-15 | 7100-18-15 | 7100-20-15 | 7100-25-15 | |||||||

| 18 | 7100-18-18 | 7100-20-18 | 7100-25-18 | ||||||||

| 20 | 7100-20-20 | 7100-25-20 | |||||||||