- Contact us

- |

- About us

- |

- |

-

- Personal information

- Organization

- Quotes

- Address book

- Login

- Don't have an account? Sign-up

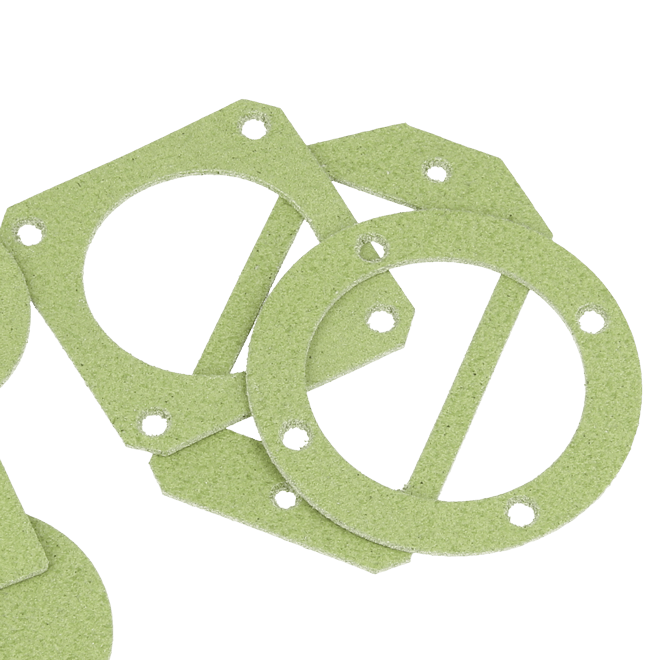

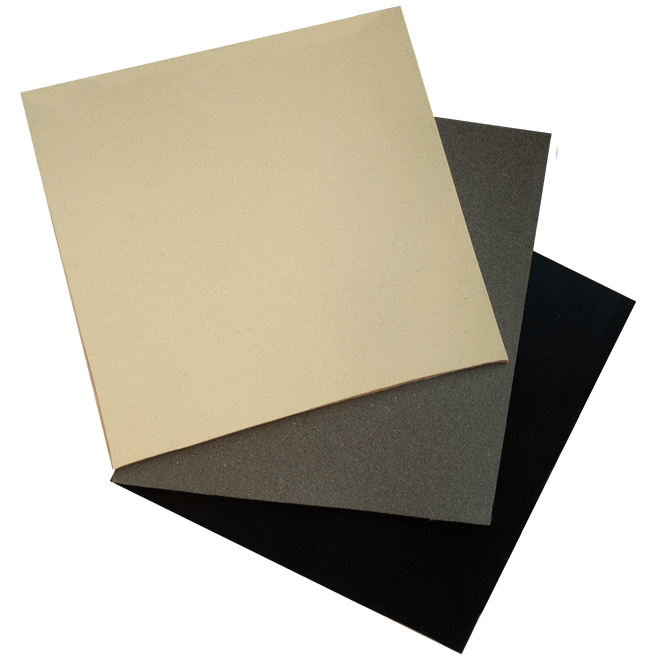

Conductive rubber sheets

- Home

- EMI shielding gaskets solutions

- EMI/IP gasket

- Conductive rubber sheets

In EMI shielding, this rubber in particular is used as a medium to provide electrical conductivity

The rubber is made conductive by incorporating small conductive metal particles throughout the material. It can provide an EMI-proof and watertight seal in narrow constructions.

Electrically conductive rubbers are typically used for EMI

applications. But they are also useful for EMP protection,

wave-guide applications and against static electricity.

The rubber can be filled with silver, nickel, silvered glass, silvered aluminium, or graphite (only for ESD). Commercial EMI applications often choose Nickel-graphite conductive rubber (Part number 5760) or Graphite conductive rubber (Part number 5755) from a costs point of view, while military and aerospace applications often call for silver plated aluminium (Part number 5750) to meet Mil-G-83528C specifications. In military or aerospace, fluorosilicone versions may also be used due to their chemical and fuel resistance.

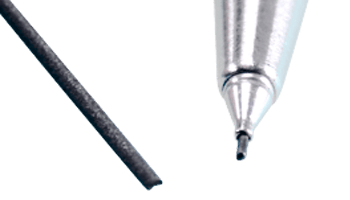

As the material shields high frequencies, electrically conductive rubber shows a shielding effect of 60 dB at 30MHz ~ 10GHz. Due to its excellent conductivity, grounding, and EMI shielding effect, it is well suited for military communications equipment. The rubber can be manufactured in various shapes such as sheets, molded parts, die-cut, strips, o-rings, etc.

Conductive adhesive information (Conductive PSA)

| Property | Unit | Outcome | Test method |

|---|---|---|---|

| Surface resistance | Ω/sq | <0.10 | MIL-DTL-83528C |

| Adhesive strength | G/25mm | 850 | ASTM D 3330 |

| Conductive PSA | - | Acrylic + Ni | - |

| Liner | - | Paper, Film | - |

| Please note: Conductive adhesive is optional. By default, these Conductive rubber gaskets are supplied without adhesive. | |||

Benefits

- Excellent conductivity on the entire surface

- Excellent electromagnetic shielding effect

- Easy die-cutting, kiss-cutting and slitting

- Temperature ranges of -60 to +185°C

(under certain circumstances, tolerance can be up to 220°C

Electrically conductive rubber

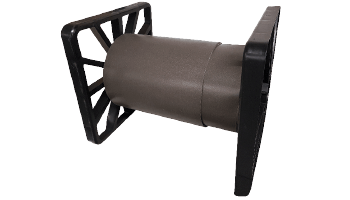

is available as

- Sheets

- Molded parts

- Die-cut or flash cut

- Silver plated aluminum conductive rubber profiles

Special materials (on request)

These conductive rubber sheets are also available in special materials for special applications for example applications with chemicals. Below is a list of special materials. For availability and delivery please email

- Silicone Carbon

- Fluorosilicone Nickel Graphite

- Silicone Nickel Graphite Flame Retardant

- Silicone Silver Aluminium

- Fluorosilicone Silver Aluminium

- Fluorosilicone Nickel

- Silver Plated Nickel

- Silvered Glass

- EPDM (thickness 1 mm)

- Silver copper silicone conductive rubber

- Compatible with MIL-DTL-83528-B

Technical properties

| Part number | 5750 silver plated aluminium |

5755 Graphite |

5760 Nickel graphite |

|---|---|---|---|

| Filler | Ag/Al | Graphite | Ni-graphite |

| Base polymer | Silicone | Silicone | Silicone |

| Width (mm) | 610 x 660 | 430 x 450 | 610 x 660 |

| Elongation, %, min. | 90 | 50 | 50 |

| Flame resistance, UL94 (horizontal) | HB | HB | HB |

| Flame resistance, UL94 (vertical) | V-0 | V-0 | V-0 |

| Volume resistance, Ohm-cm (expression of conductivity) |

0.008 | 1.8 | 0.05 |

| Surface Resistance, Ω/sq | 2 | 3-5 | |

| Operating temp. | +125 | +160 | +160 |

| Range (°C) | -55 | -50 | -55 |

| Colour | Dark tan | Black | Dark grey |

| Shore Hardness (A +/-5) ASTM D2240 | 65 | 60 | 60 |

| Volume Resistivity (ohms) ASTM D991 | 0.005 | 2.2 | 0.04 |

| Shore A (1 mm thickness) | 73 | 71 | 70 |

| Shore A (2 mm thickness) | 70 | 75 | 60 |

| Tensile strength. psi, min. | 90 | 50 | 50 |

| Cost | $$$ | $ | $$ |

| Conductivity | *** | * | ** |

Shielding performance

Please note : These values are measured under laboratory conditions. Results may vary in other situations; please read our guarantee.

What questions need to be answered to select the right material?

- What is the approximate shielding effectiveness you need to achieve for your application?

- What environment will this material be exposed to? Does the rubber need to be solvent or fuel resistant (fluorosilicone)?

- Are you looking for a semi-conductive/static dissipating material or is this a true EMI/RFI shielding application?

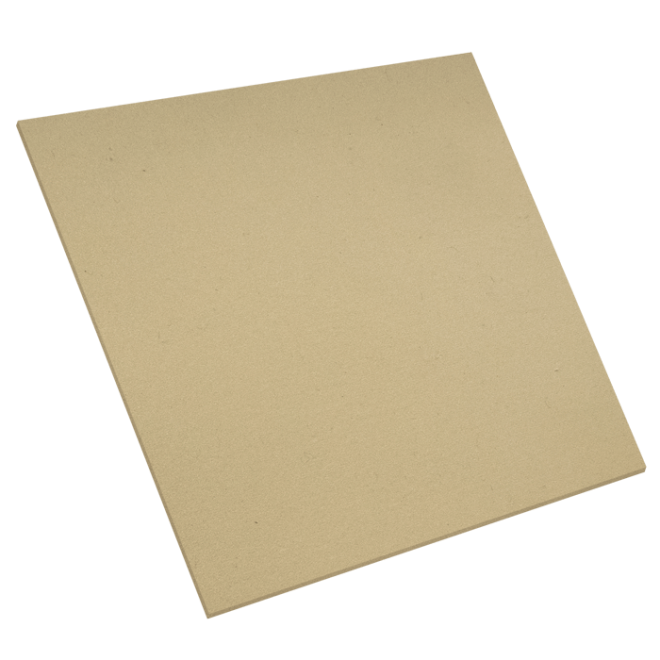

Silver plated aluminium (Dark tan) 5750

| Ag/Al Silicone conductive rubber (silver plated aluminium) 5750 |

|

|---|---|

| Thickness (mm) | 0.3, 0.5, 1.0, 1.2, 1.5, 1.7, 2.0, 2.5, 3.0 |

| Part number | 5750S |

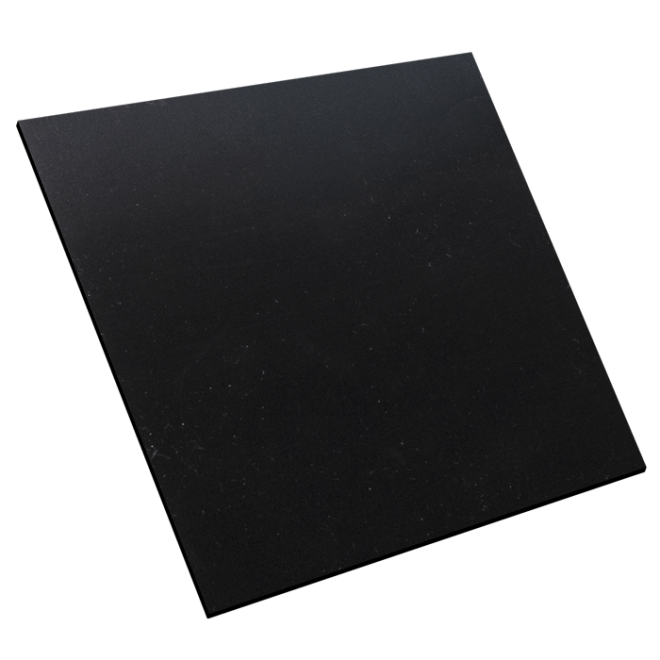

Graphite conductive rubber (black) 5755

| Graphite conductive rubber (black) 5755 |

|

|---|---|

| Thickness (mm) | 1, 2, 3, 4, 5, 10 mm |

| Part number | 5755S |

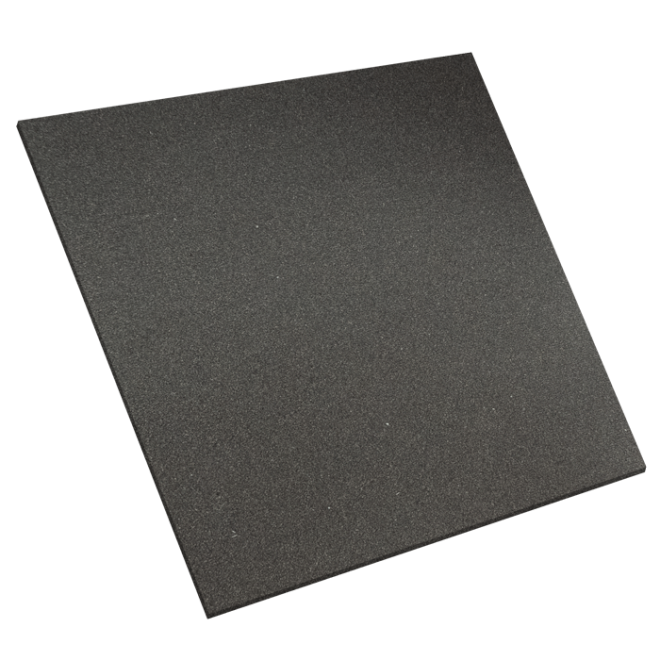

Ni-Graphite conductive rubber (dark gray) 5760

| Ni-Graphite conductive rubber (dark gray) 5760 |

|

|---|---|

| Thickness (mm) | 0.3, 0.5, 1.0, 1.2, 1.5, 1.7, 2.0, 2.5, 3.0 |

| Part number | 5760S |