- Contact Us

- |

- Jobs

- |

- About Us

- |

- |

-

- Personal information

- Organization

- Quotes

- Address book

- Login

- Don't have an account? Sign-up

Transparent EMI/RFI-shielding foil window

- Home

- EMC windows, EMI displays & conductive transparent sheets

- Transparent EMI/RFI-shielding foil window

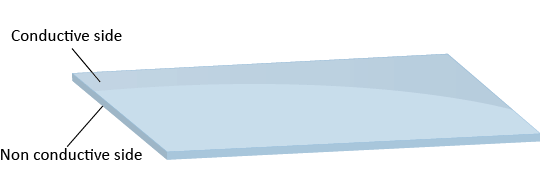

Transparent EMI/RFI-shielding foil windows 9910 series consist of a strong polyester film with a layer of transparent conductive coating from our 9900 series Transparent shielding foil laminated on one side of a single glass or plastic window.

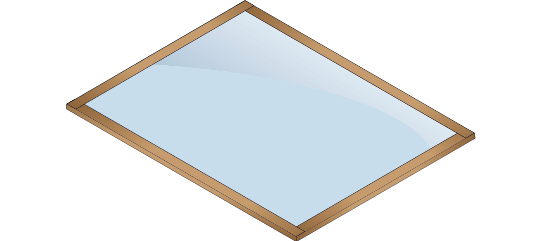

Transparent EMI/RFI-shielding foil 9910 series can also be laminated onto an existing window, if the window is brought to us, or onto any new window made of:

- Polycarbonate (material code P)

- Acrylic (material code A)

- Glass (material code G)

Shielding performance

Mounting

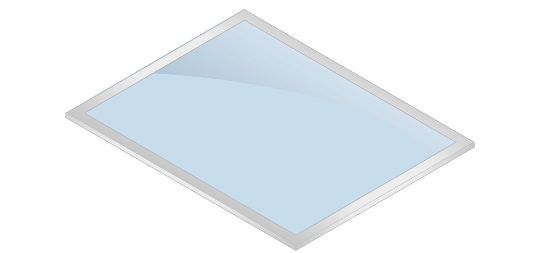

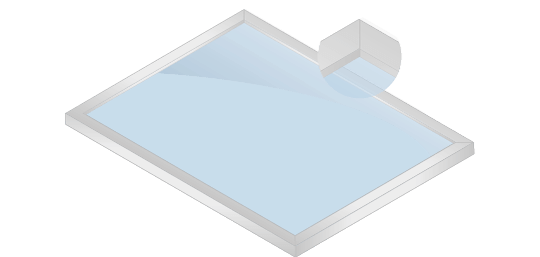

Connection from the conductive side of the Transparent EMI/RFI shielding foil 9900 series to a conductive mounting surface of the construction can be provided by Shielded tape 3201 series or by clamp-mounted Ultra soft shield 7400 series.

Technical drawing

Contact edges

EMI/RFI-shielded glass 9600 series is conductive on one side. If you want to establish a connection with the other side of the glass which is not conductive, a contact edge is needed.

(C) With copper edges for grounding

(TC) With tinned copper edges for easy soldering and grounding

(S) With a silver busbar

(F) With aluminium frame for shielded enclosures, Faraday cages and MRI rooms

(N) Without a special contact edge; there still is electrical conduction at the coated side of the glass.

Please note: the top layer can be affected by acid, for example from the skin. To protect the conductive layer, you can apply a transparent film or use the non-conductive side on top.

Small optical defects are allowed in this product. If you need a product that is absolutely free from optical defects, please contact us for the "superior selected quality". Do be aware though that due to the extreme caution required to manufacture these products, they can be several times more expensive.