- Contact Us

- |

- Jobs

- |

- About Us

- |

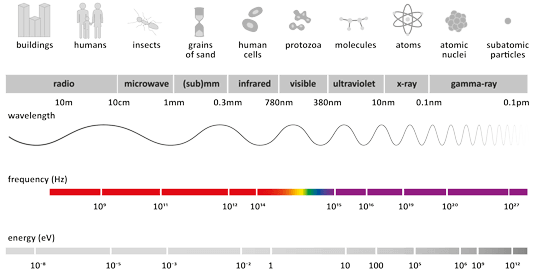

- |

-

- Personal information

- Organization

- Quotes

- Address book

- Login

- Don't have an account? Sign-up

101 EMI Shielding Tips and Tricks

- Home

- 101 EMI Shielding Tips and Tricks

Discover 101 straightforward tips and tricks for EMI shielding, organized across three proficiency levels. This includes fundamental shielding principles and a variety of general tips.

Principle of shielding

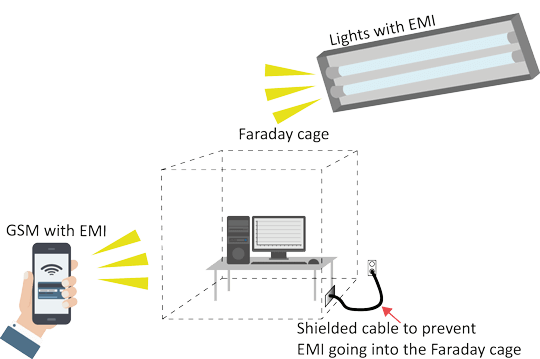

1 The principle of shielding is creating a conductive layer completely surrounding the object you want to shield. This was invented by Michael Faraday and this system is known as a Faraday Cage.

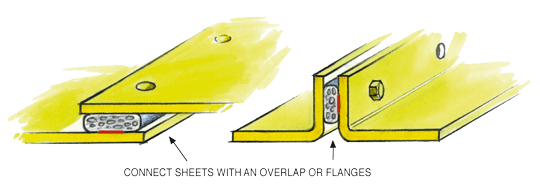

2 Ideally, the shielding layer will be made up of conductive sheets or layers of metal that are connected by means of welding or soldering, without any interruptions. The shielding is perfect when there is no difference in conductivity between the used materials. When dealing with frequencies below 30 MHz, the metal thickness affects shielding effectiveness. We also offer a range of shielding methods for plastic enclosures. A complete absence of interruptions is not a realistic goal since the Faraday cage will have to be opened from time to time so electronics, equipment, or people can be moved in or out. Openings are also needed for displays, ventilation, cooling, power supply, signals, etc.

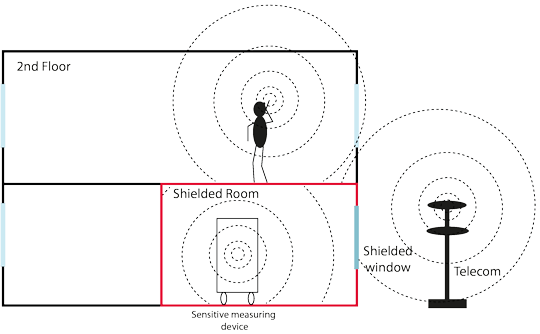

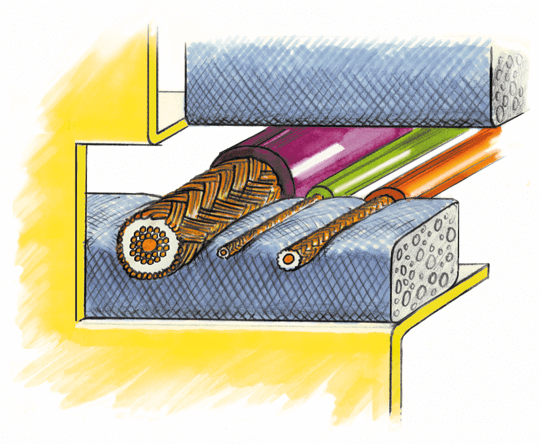

3 Shielding works in both directions, items inside the shielded room are shielded from outside influences. (Fig. 3.1)

Figure 3.1: Shielding works in both directions

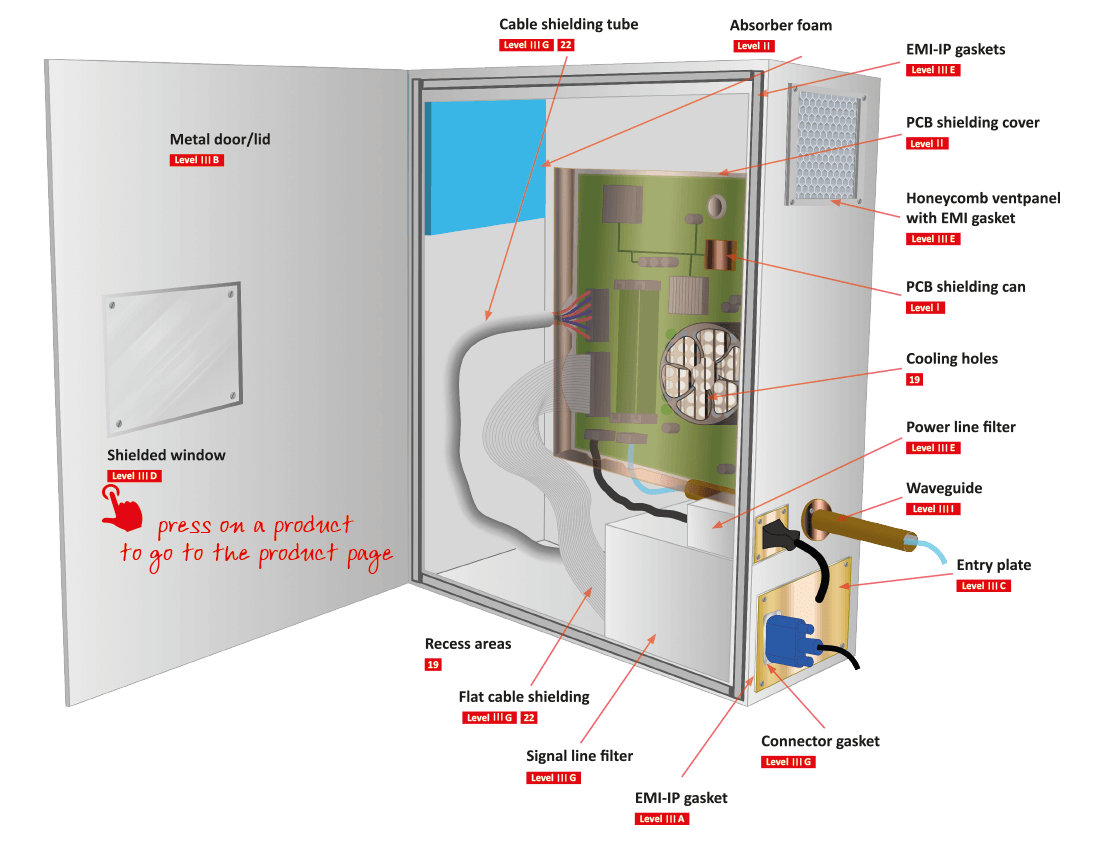

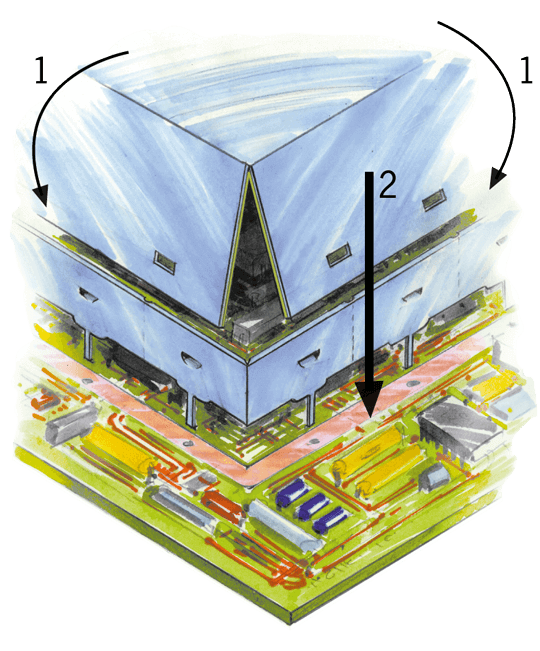

4 The quality of the cage is expressed as the ratio of the field strength in Volts/meter (V/m) inside the cage and outside the cage.

5 It is common practice to present field strength Figures in a logarithmic scale (in dB).

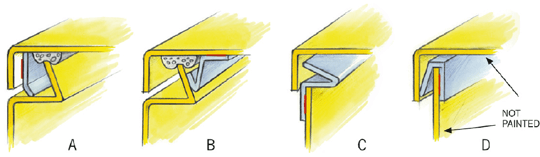

6 The reduction depends on the frequency in Hz. Each frequency has a wavelength in meters. For example 100 MHz = 100.000 kHz = 3 meter. For a better explanation, see the table below.

| 40 dB | 100 times reduction of the field strength |

| 60 dB | 1.000 times |

| 80 dB | 10.000 times |

| 100 dB | 100.000 times |

| 120 dB | 1 million times |

| 140 dB | Very difficult to measure and only used in scientific applications |

Waves

7 A wave is a combination of electric field and magnetic fields.

An electromagnetic wave is composed of a magnetic part depending on the electric current (ampere), and an electrical section, depending on the electrical voltage (volts). Near the source (near-field) the magnetic part is dominant. At a greater distance, the electrical part and the magnetic part are present in a fixed ratio (far-field). (Fig. 7.1)

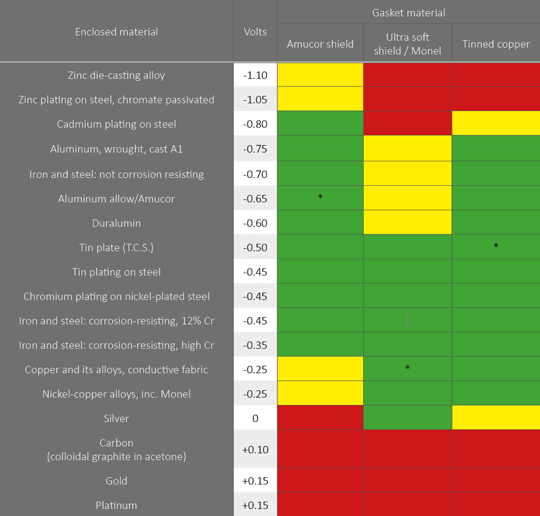

Figure 7.1: Wavelength vs. Frequency

8 The material thickness determines which frequencies are blocked from penetrating into or out of the cage. For low frequencies like 10 kHz (generally the near-field/magnetic fields), a mild steel layer of 6 mm is needed to achieve a reduction of 80 dB, but a frequency of 30 MHz can be shielded by a copper foil that is only 0.03 mm thick. For higher frequencies in the GHz area, the mechanical strength of the used shielding material will generally specify the thickness of the shield.

9 For very low frequencies and DC, where the magnetic field is dominant, besides thick layers also special materials like Mu-metal and Mu-ferro alloys are needed. In addition, combinations of multiple layers are required to get sufficient shielding performance. Please consult our engineers.

10 When a wire penetrates a shield that is not completely connected to the shield, it will work as an antenna and this reduces the shielding performance of the cage. This is especially the case at higher frequencies. (Fig. 10.1)

Figure 10.1: Wires penetrating a shield

Why the Faraday cage principle for EMI shielding?

11 Circumstances in which EMI shielding has to be implemented

- When a product has to meet government standards like CE or FCC which regulate immunity and compatibility of products.

- The regulations do not cover the requirements of daily practice

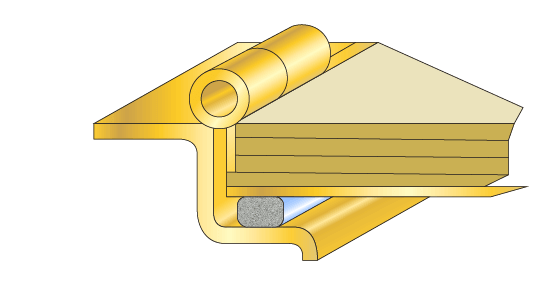

(e.g. medical instruments are tested at 3 meters distance while they are used within 15 cm). - Extra safety is desired for military use, e.g. for EMP (electromagnetic pulses). – see https://en.wikipedia.org/wiki/Tempest_(codename)

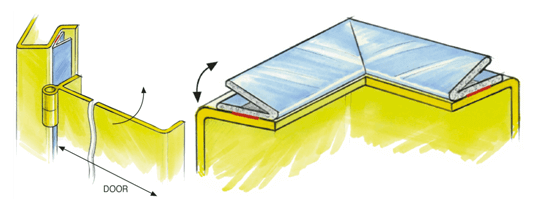

- Sensitive instruments or equipment are to be protected from interfering or harmful frequencies.

- Rules for sensitive measuring and weight equipment like balances and petrol-delivery materials have to be met.

12 Other aspects related to shielding

- Regulations regarding ESD (electrostatic discharge)

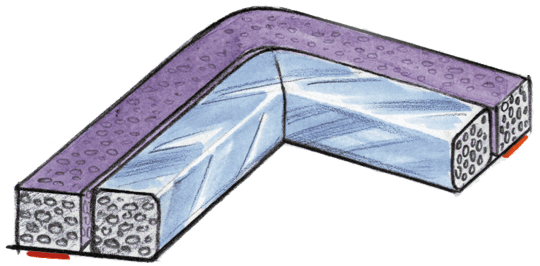

- Regulations regarding ATEX (explosion safety)

- Lightning protection / EMP / HEMP / NEMP

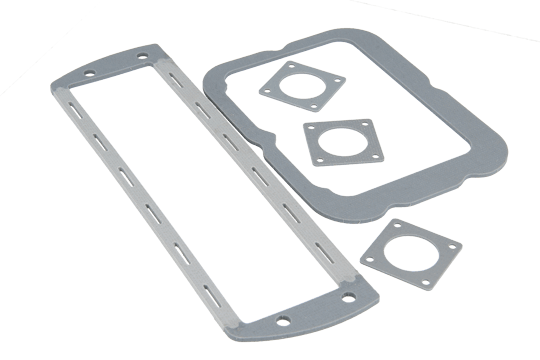

- Short circuit protection / prevention of sparks

13 Identification systems like RFID (Radio Frequency Identification). Prevent RFID from making contact with the stations.

Several frequency ranges, lower frequencies are for longer distances

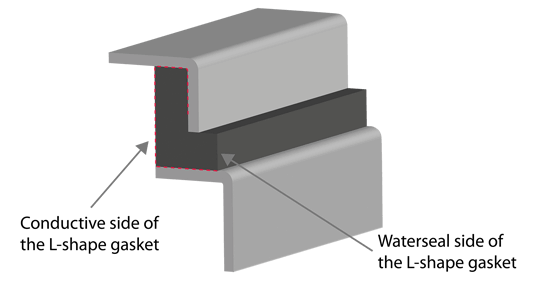

- 125 kHz (Low Frequency)

- 13.56 MHz (High Frequency)

- 860 to 950 MHz (Ultra High Frequency)

- 2.45 GHz (Microwave)

14 Medical/personal protection

Shielding certain frequencies can prevent illness caused by radiation levels. Protective clothing can reduce field strength, depending on the density. To this end, there is personal protection in the form of sleeping bags, tents, and so on.

How to create optimal EMI shielding

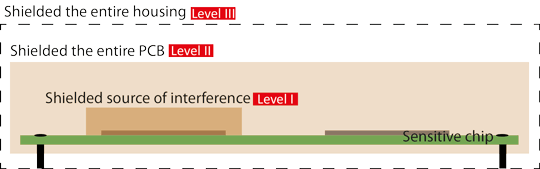

15 In general, a shield consisting of more layers or zones is cheaper to produce than a shield made out of 1 high-performance layer. It is easy to create 3 zones:

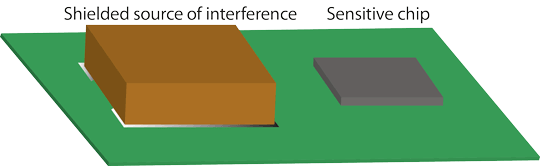

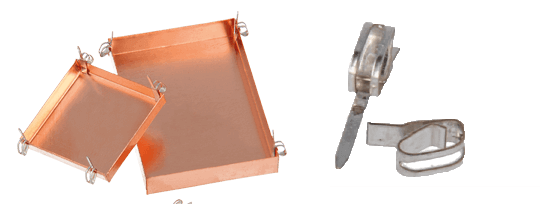

LEVEL I The component on the PCB is shielded by a can. Shielding at the source (fig. 15.1)

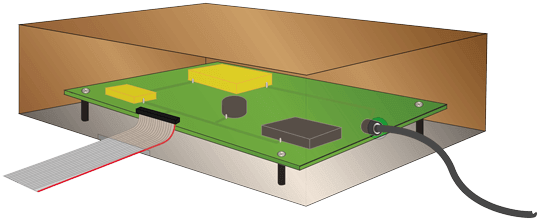

LEVEL II The entire PCB is shielded by foil, wraps or a box (fig. 15.2) or the PCB and all the cables connected to it are inside the shielded box

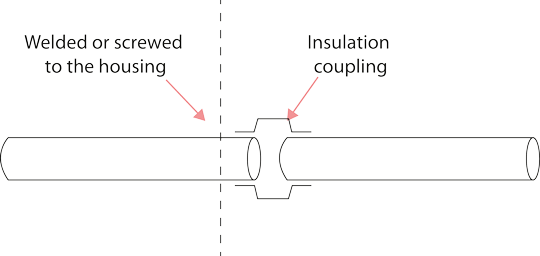

LEVEL III Or the outer housing is shielded as well (fig. 15.3).

Figure 15.1: Shielding at the source

Figure 15.2: Shielding the entire PCB

Figure 15.3: Shielding in three levels, see tip 16 - 24

Shielding at the source

LEVEL I 16 Source

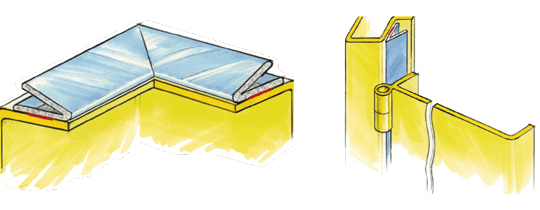

Shielding at the source is usually the most cost-effective solution. Generally speaking, the source of unwanted radiation can be produced by voltage and current through one or more components or interconnections on the PCB.

The application of shielding can reduce it directly at the source.

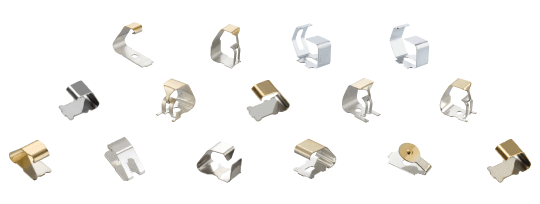

LEVEL I 17 Clip mounting

Shielding cans are mounted onto the PCB with SMD clips, which come in several sizes. After the re-flow, the can (a cover with walls attached) is placed into the clips and can subsequently be removed for adjustments. (fig. 17.1)

Figure 17.1: SMD clip for mounting PCB shielding cans

LEVEL I 18 Pin mounting

There are also systems with pins for through holes or covers with integrated pins that can be soldered directly onto the PCB. (Fig. 18.1)

Figure 18.1: Pin mounting used to mount PCB shielding cans

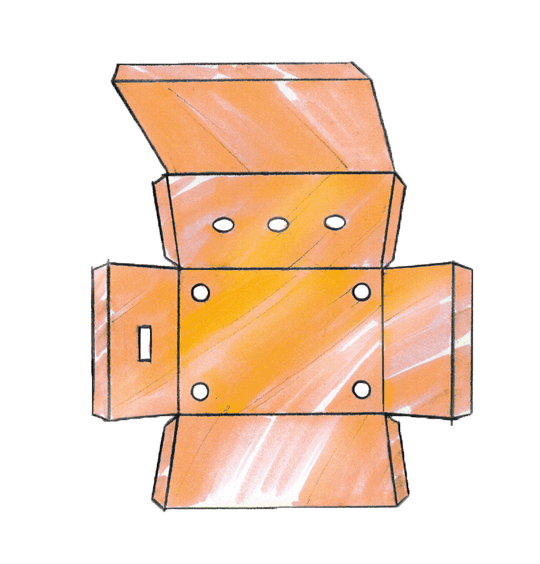

LEVEL I 19 Shield layout

Cooling holes can be made in the cover or steps to prevent short circuits with the tracks on the PCB. (Fig. 19.1)

Covers can also consist of a fixed part on the PCB (fence) and a separate cover that is clipped on to this fence. (Fig. 19.2 and Fig. 19.3)

Figure 19.1: Example of a shield layout with holes and openings for cables

Figure 19.2: Fixed part on the PCB (2. fence) and a separate cover (1)

LEVEL II 20 Covering the entire PCB

Another option is covering the entire PCB in shielding material. This can be achieved either by means of small housing, custom-made to exactly the right shape, or by simply wrapping or sticking material around the PCB.

Foils, textiles, stretch material, and wrap shields, cut to the appropriate shape, are easy to apply. Since it is always important to prevent short circuits, all materials can be provided with insulation layers.

Cable shielding

LEVEL II 21 Cables inside the housing

Once the PCB is covered, the attached cables can also be shielded. The longer a cable, the higher it's potential for emitting lower frequencies. Shielding a wire inside the enclosure will also prevent cross-talk and will make the main enclosure act as a cavity, and thus amplify the radiation. To prevent this, the enclosure can be (partly) laminated with EM absorption material. (Fig. 21.1)

Figure 21.1: Flat cables, round cables, bundles of cables and branches can be shielded

LEVEL II 22 For round and flat cables we produce shields in the shape of sleeves, wraps, tubes, and textiles so that all types of cables can be shielded. Some cable shields need to be grounded at both ends, but it is usually best to ground at only one end to prevent common-mode currents.

LEVEL III 23 The housings themselves, i.e. the rack, the box, the enclosure, the metalized box, and the Faraday cage they constitute the main cover of the entire system and also the connection to the outside world. Housings are equipped with displays, entries for power and signal lines, and cooling air-vents. For more information see the case at the beginning of this article.

LEVEL III 24 Elements that can reduce the effectiveness of a Faraday cage

- LEVEL III A Seams (fig. 24.1) 26 / 32

- LEVEL III B Doors 45

- LEVEL III C Entries 10, 63 / 69

- LEVEL III D Transparent displays 70 / 74

- LEVEL III E Ventilation panels 79

- LEVEL III F Cables for power supply 64 / 69

- LEVEL III G Cables for signals 65

- LEVEL III H Pipes for fluids, air, heating (fig. 24.2) 64 / 69

- LEVEL III I Cables for optical connection 64 / 69

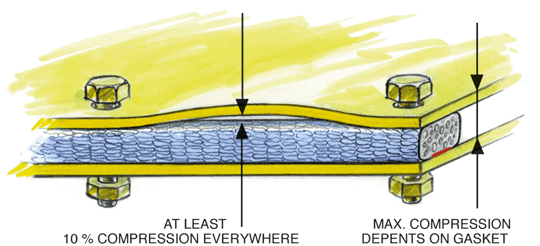

Figure 24.1: Note that the pressing force on the panels of the housing is not too large

Figure 24.2: Pipes of conductive material need to be provided with insulating couplings

Seams

25 It is important for the conductivity of the seam to be more or less identical to that of the basic material that the cage is constructed out of. Welding or soldering tends to work best, but for places that have to be opened easily several mechanical connection methods are available: clamping, screwing, adhesive, sealing and sticking.

26 Characteristics of an optimal seam

- It is flat and smooth 27

- It has the right dimensions (fig. 26.1) 32

- The construction is stiff enough (fig. 26.1) 41 / 44

- It is and will remain free of corrosion (fig. 26.2) 33

- If possible, it is in a single plane

Figure 26.1: Examples of right dimensions and a stiff construction to prevent openings

Figure 26.2: An EMI gasket combined with an environmental seal can prevent corrosion and water coming into the device

27 A superior flat surface can be achieved by machining and finally grinding the top surface. This is an expensive process and requires a stiff construction.

28 To reduce cost, the connection can be improved by using a

conductive gasket, which will fill in any gaps. A gasket can also be used to seal against water or to meet other IP demands. (fig. 26.1) (fig. 26.2).

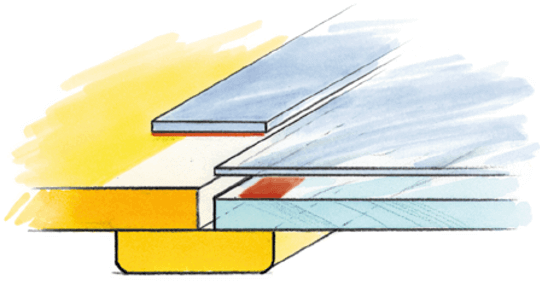

29 The softer the gasket, the more tolerance can be compensated and the lighter the eventual construction will be. (fig. 29.1).

Figure 29.1: Example of a very soft EMI gasket so that more tolerance is allowed

30 If more tolerance is allowed, a less accurate production method can be used and production becomes more cost-effective. (fig. 29.1).

31 A lighter construction can also be realized by having smaller distances between the fixings: this results in more hinges, more locks, and more bolts. All of these extra elements result in higher costs and longer mounting and demounting times.

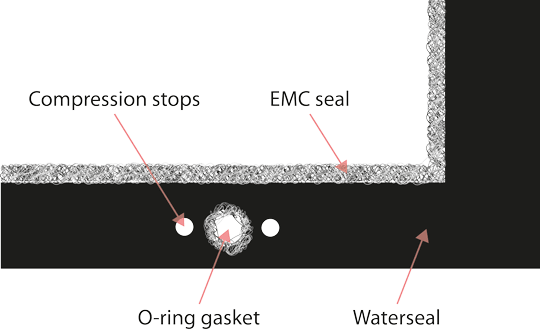

32 Right dimension It is possible to integrate an IP sealing with the EMI gasket. The IP gasket on the “water side “ protects the EMI gasket from corrosion.

Prevention of corrosion

33 In the design stage it is important to specify the environment.

It makes a difference whether the construction has to be able to withstand only humidity, or exposure to water (possibly even salt water), fog, or condensation, e.g. during transport.

34 If the metal of the housing is sensitive to corrosion, a finishing of e.g. nickel and chrome can help the contact surface maintain the required conductivity. Materials like aluminum and zinc-plated steel develop an oxidation layer, which reduces the corrosion process but is less conductive.

35 Galvanic corrosion

Even when the materials of the housing withstand corrosion well, it is important that they work together not only with one another but also with the gasket (fig. 35.1).

Figure 35.1: Galvanic corrosion table

36 Sea/water environment

In a situation where the galvanic values of the gasket and the housing material differ more than 0.3 volts in a salty environment, or 0.5 volts in an environment with just water, galvanic corrosion will occur. Even at a distance of 10 km from the sea, the atmosphere may be as salty as right on the coast. So the appropriate gasket material has to be chosen, see gasket selection graph.

37 Around the bolt holes should be sufficient space for a water seal. Water should never reach the EMI gasket or the construction via the bolt holes. Alternatively, extra water sealing can be applied around the bolts in the form of rings. (fig. 37.1).

Figure 37.1: EMC / IP gasket example

38 For small parts, where there is less space a gasket out of e.g. electrically conductive rubber can be used. These are available in profiles and plates, which can be cut accurately to the required dimensions.

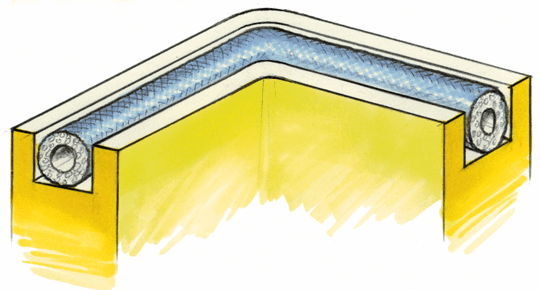

39 For bigger parts, it can be more efficient to use a combined gasket. An EMI gasket with a water seal made of neoprene, silicone or EPDM rubber. (fig. 39.1)

Figure 39.1: Combined gasket (Waterseal combined with EMC seal)

40 Neoprene has quite good flame retardant properties and can handle temperatures of -40 to +100 °C. EPDM rubber can withstand temperatures up to 120 degrees, making it suitable for the engine compartment of cars.

Silicone rubber is used for temperatures up to 220 °C; it can be sterilized for medical applications and is soft. The rubbers can either be made in the shape of a foam or mousse or as a solid product.

Rules of thumb for gasket choice, DEPENDING ON THE TYPE OF ENCLOSURE

41 Very small construction, (smaller than 150 x 150) grooves, casted, molded or machined: conductive profiles, o-ring or cut gasket out of highly conductive rubber are suitable (fig. 41.1).

Figure 41.1: Groove construction with conductive o-ring gasket

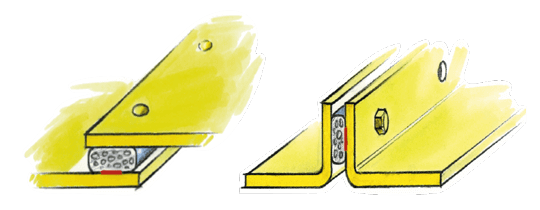

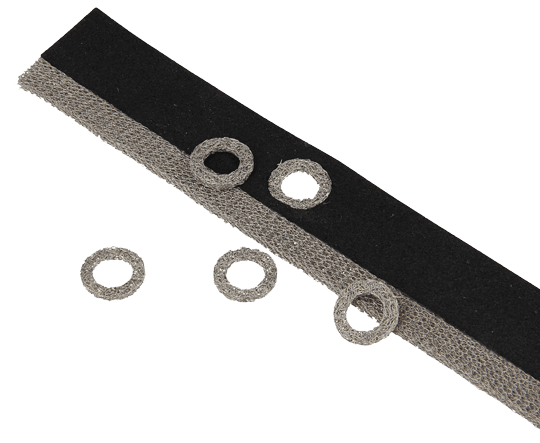

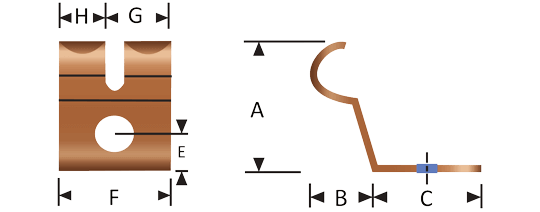

42 Small construction, (about 200 x 200mm) multi-shield gasket, consisting of metal wire from top to bottom through a soft silicone rubber with a thickness of 2-3 mm are suitable. (fig. 42.1).

Figure 42.1: Examples of gasket solutions for small constructions

43 Medium size construction, zinc-plated steel/metal: standard shield, neoprene foam with water seal, minimum width about 4mm and thickness 2-3 mm. (fig. 43.1).

Figure 43.1: Examples of gasket solutions for medium size constructions

44 Full-size rack with a door. Ultra-soft twin shield with separate water seal or knitted mesh over silicone tube with water seal, V-shape with additional water sealing, thickness 6-10 mm is suitable. Other products like finger strips, textile-covered parts, clip-on gaskets or custom build hybrid gaskets are suitable. (fig. 44.1).

Figure 44.1: Examples of gasket solutions for larger constructions like server racks

Shielded Doors

45 The closing force of a shielded door/Faraday cage door should be reduced as much as possible so that it can be opened by hands. For more information read 55

Figure 45.1: Construction of a shielded door

46 Gasket thickness

Ultra-soft gaskets will help limit the closing force as well as bending of the door. (fig. 29.1).

47 Just as indication, at a server cabinet of 600 x 2500mm, a gasket of 6mm thick may be used and an electronics housing 200x600mm a gasket of 6 x 4mm is an optimal size. All our gaskets can also be provided with water sealing. In order for a gasket to have sufficient stability, its width should exceed its height.

48 In the case of a screwed connection at a housing, entry panels, windows, or vent panels, the closing force is less important. Depending on the plate thickness and bolt distance, 1-2 mm is common and amucor shield is a very good choice for the materials used most often.

49 When the housing has only one edge flange while a water and EMI seal are needed, this can be created by using clip-on gaskets. Of these gaskets, more than 200 different shapes have been produced edged with mesh or highly conductive textiles. They are mounted by means of clamping. When we cut them into shape according to the customer’s wishes, they can even make angles of 90 degrees.

50 For instruments and introducing high currents into a construction we make over 2400 different Be-Cu finger strips. These are not allowed in every country and are susceptible to being damaged when they are used in a construction that is not protected properly (knife-edge).

51 Gaskets can be made in the shape of a frame, complete with mounting holes and self-adhesive strip for mounting if desired. (fig. 51.1).

52 In order to keep a gasket from becoming overly compressed, it is possible to add compression stops next to the bolt holes. If there is enough space, plastic or metal rings (compression stops) with the final thickness can be integrated into the gasket.

53 For easy mounting, there are gaskets in a P-shape or U-shape available. These gaskets can be easily mounted on a rim due to their shape. (fig. 53.1).

54 L-shaped gasket can be used in constructions where EMI with water sealing is required and when there is just one flange. Maximum compression is 30%. (fig. 54.1).

55 To prevent high closure force V-shaped gaskets can be used which clamp the door not in the direction of the opening but in the direction of the door, so only the friction force is the closing force. (fig. 55.1).

Figure 55.1: V-shape gasket to prevent high closure force

56 For special constructions, our custom-built profiles can help to create an optimal seal.

57 Watertight EMI gaskets in any shape can be cut out of sheets of material like conductive rubber, or multi-shield with small conductive wires in the material. They have a compression of 10-15%. (fig. 57.1).

Figure 57.1: Conductive rubber gaskets can be cut in any shape according to customer drawing

58 Conductive foam is an open structure so it is not watertight, but it can be combined with a watertight neoprene gasket.

59 Knitted mesh for military and low-frequency use is available made out of full metal (10-15% compression) neoprene foam covered with knitted metal wires which have 30-40% compression. Silicone tube covered with knitting has up to 50% compression and low compression force.

60 The knitted-mesh gasket can be mounted into a groove or can be produced with a fin so that it can be screwed or clamped.

61 When there is no groove in your construction the knitted wire mesh gasket can be glued to self-adhesive rubber, to keep it in place.

62 For high-performance gaskets to seal gaps in, for example, Faraday cages for sensitive measurement the gaskets can be produced in a double implementation and bolted in the centre.

Cable shielding

63 Cables entering a Faraday cage can carry undesirable signals into and out of the housing. When these cables are shielded, the cable shield should be 360 degrees around the cable, and be connected to the housing using a gland or cable entry plate. Entry shielding is also available in watertight and flame retardant versions. Power lines and signal lines should be filtered when it is not certain what frequencies are on the line. (Fig. 63.1)

Figure 63.1: Cables entering a Faraday cage can carry undesirable signals

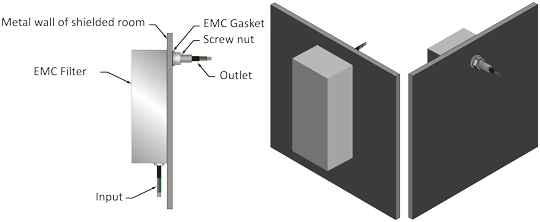

64 Filters for power, signals and data. A power line coming from the grid function as an antenna of immense length and brings many unwanted frequencies with it. It has to be “cleaned” by a filter before entering the shielded room. The same goes for signal lines and pipes going into the housing. They will work as an antenna and interfere with the shielding. (Fig. 64.1)

Figure 64.1: Example of a power line filter mounted on a Faraday cage wall

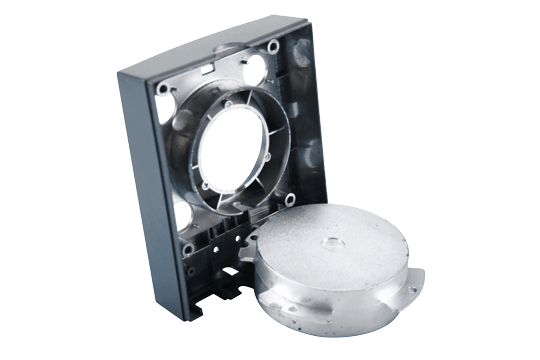

65 Shielding for data lines is done by converting the signal to light and bringing the signal into the shielded room via a fiber optic cable through a waveguide. The fiber optic cable is non-conductive and will not bring in unwanted signals. (fig. 65.1).

Figure 65.1: Example of a fiber optic converter combined with a waveguide

66 A power- or signal line filter should be grounded to the Faraday cage so that there is a connection with a low impedance to the body of the shield. This is needed for discharging unwanted signals.

67 It is best to position all filters close together but to separate the signal line filters away from the power line filters to prevent currents through the cage wall from the power line filters interfering with the signal line filters.

68 The shielded housing creates a new “ground” and should be connected to the common ground of the building, only for safety reasons. This is to prevent voltage on the cage in respect to the earth.

69 When you want to enter a clean ground line inside the cage, other than the earth line of the housing you also need a ground line filter for this extra clean ground line.

Displays

70 Products for transparent shielding

- Woven mesh 73

- Woven mesh between sheets of acrylic, polycarbonate or glass, connected at the edges (edge bonded) (fig. 73.1) 73

- Woven mesh, fully laminated between plates of acrylic, polycarbonate or glass (fig. 73.1) 73

- Woven mesh between foil with or without self-adhesive (mesh foil) 73

- Indium tin oxide (ITO) on foil or glass, 4 or 6mm (transparent foil) (fig. 74.1) 74

- Copper grid on foil, high light transmission versus shielding performance

- High performance combinations of above materials, framed in metal with gaskets for easy mounting (fig. 75.1) 75

- Transparent foil with an anti-static layer (ESD foil)

71 Mounting a transparent window

In order to ensure good shielding performance, a transparent conductive shield can be provided with a silver contact busbar. Some shields can be made with flying mesh so that the flying mesh can be connected to the shielded housing. The shielded window should make full contact with the housing on all its sides by means of conductive adhesives, conductive seals, tape with conductive adhesive, or clamping with a gasket if desired. (fig. 71.1).

Figure 71.1: Example drawing of a clamp structure for mounting a transparent shielding solution

72 Conductive foils can be stuck to a standard screen or window with cleanly removable self-adhesive. More rigid transparent shields can be made with a frame or mounted with a bezel.

Warning

It is currently not possible to make transparent shields 100% optically correct because of the so called moiré effect, so minor disturbances have to be accepted.

Choice of transparent material

73 Mesh foil

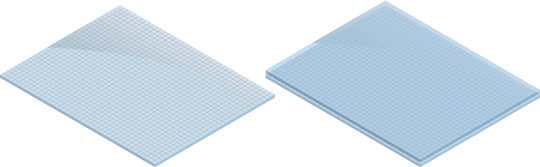

For shielding at low frequencies, mesh shielding types show the best performance. They have lower light transmission than for example ITO coated windows and foils but that is considered normal for a display rather than a problem. (Fig. 73.1)

When the foil is applied to a monitor and the lines of the mesh in the film do not correspond with the dots of the monitor Newton’s ring effect or a moiré pattern will arise. Orienting the mesh at a certain angle between 17 and 45 degrees will minimize this effect. Please note: there is a physical rule: the finer the mesh, the darker the material, the better the shielding performance.

Figure 73.1: Example of a single mesh foil window (mesh bonded on the top of a window) and a stepped mesh foil window (mesh between two layers of glass or plastic)

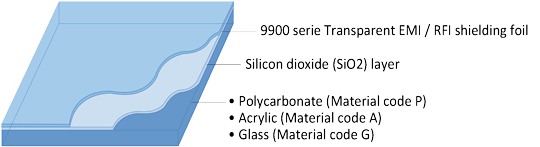

74 ITO Coating

Indium tin oxide coating does not produce a moiré effect and offers good shielding at higher frequencies. The product is however sensitive to acid substances, such as for instance found in fingerprints. Optionally a plastic film layer may be applied in order to protect the ITO layer. (fig. 74.1).

Figure 74.1: Possible structure of an ITO window

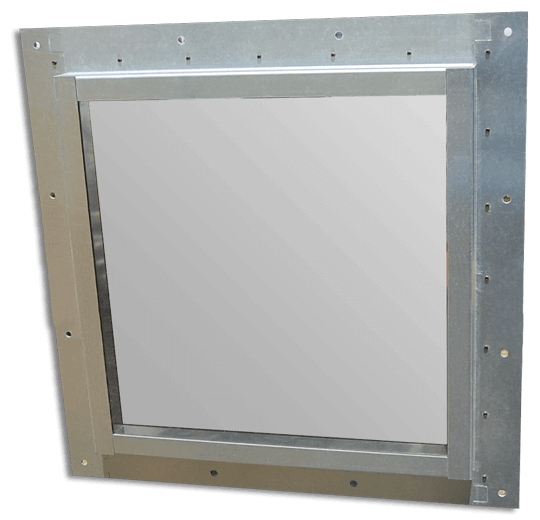

75 Framed windows

We produce turnkey shielded windows with up-to and even over 100 dB attenuation that can be installed directly into an MRI room. These windows are framed and have several layers of shielding, all of which are connected to one another. (fig. 75.1).

Figure 75.1: Example of a framed ready to install high-performance shielding window

Shielding methods for plastic housing

76 It is possible to apply a shielding foil inside the housing, either completely or partially glued to the housing. With the use of stiffer foils, a shielded box can be created inside the plastic housing in cases where there is no need to have the housing fit a specific shape. Lips on the precut foil can be used for grounding and/or mounting.

77 For housings with complex shapes, a shielding paint or spray (in cans) can be used. The paint is filled with conductive metal particles like nickel, copper, silver or combinations.

78 Metallization under vacuum (sputtering) is another option; this can also be done partially. Since a jig is needed for this process, it is not recommended for small production amounts. (fig. 78.1).

Figure 78.1: Example of plastic housings with shielding paint

79 Parts can be subjected to galvanic treatment when dealing with larger quantities.

Ventilation panels

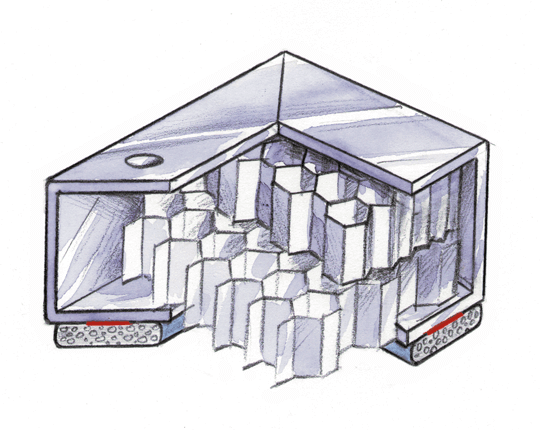

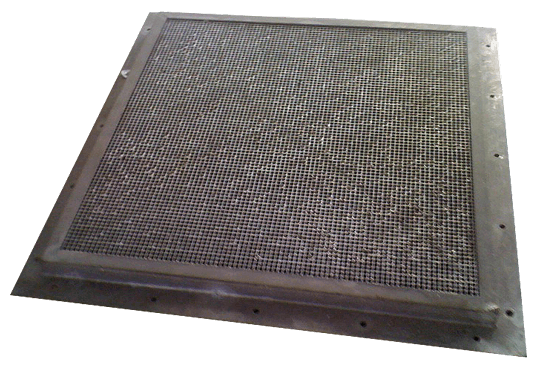

80 Within a few days, we can produce Honeycomb ventilation panels according to the customer’s drawing. The honeycomb structure is like waveguides and lets air through while blocking electromagnetic waves from entering.

The cell size of the honeycombs is 3.2 mm and combinations of several layers is possible, even under cross constructions for higher performance. A cross cell honeycomb consists of minimal two layers of Honeycomb material stepped and rotated 90 degrees relative to each other. This results in a good shielding performance independent of the polarization of the waves. (fig. 80.1).

Figure 80.1: Example of a cross-cell Honeycomb ventilation panel

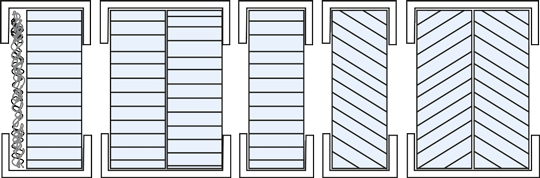

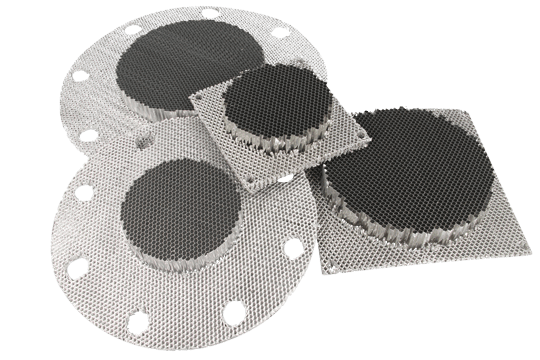

81 To protect from dust, a dust filter can be integrated in the ventilation panel. The dust filter can also be mounted to the outside of the enclosure. (fig. 81.1).

Figure 81.1: From left to right, Honeycomb with dustfilter, cross cell, single-cell straight, single-cell slant 45 degrees, double slant to prevent eavesdropping

82 The standard cost-effective honeycomb is made of aluminum but for special applications like EMP, it can also be made out of mild steel, which is more expensive. (fig. 82.1).

Figure 82.2: Picture of an EMP proof Honeycomb ventilation panel

83 A honeycomb ventilation panel can be framed and pre-drilled on request for easy mounting or can be produced frameless with optional a pressed flange for smaller constructions or when the honeycomb ventilation panel is mounted in a clamped construction.

84 For outdoor use, the honeycomb can be treated with a nickel or other finish. This is to protect the honeycomb ventilation panel from environmental influences such as corrosion. (fig. 80.1).

85 To keep raindrops from falling into the enclosure we can also make the honeycomb at a slant (45 degrees is standard) (fig. 81.1).

86 Two layers of slanted honeycomb placed opposite to one another also make it impossible for metal rods to be entered into the cage and thus protect from electrocution.

87 Mounting framed honeycombs can be done via through holes or threaded holes which are flow drilled into the frame in order to achieve a good screw length. Flow drilling is better than using rivets which may become loosened.

88 Honeycombs can also be used as flow straighteners since the structure of the honeycomb material ensures that air is blown in a fixed direction.

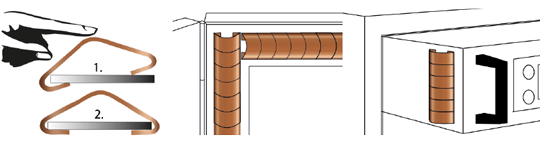

89 The honeycombs can optionally be provided with a flange so that after mounting the honeycomb forms one whole shape with the shielded enclosure. (fig 89.1 & fig. 89.2).

Figure 89.1: Picture of a frameless Honeycomb

Figure 89.2: Drawing of a frameless Honeycomb construction

Cables

90 Cables from and to a shielded enclosure should also be shielded when no sufficient entry like power line filters are used.

91 Optimal cable shielding can be achieved with several materials like conductive flexible shielding tubes, wraps made of knitted metal, highly conductivity textiles or foils. All these materials can be supplied with- or without self-adhesive

92 The cable shield should be low impedance connected at the entrance of the screen, wall or body of the shielded enclosure. That way there is not only a galvanic connection but this also creates a high-frequency coupling.

A full 360-degrees connection around the cable works best. For this purpose, we produce cable entriess (fig. 92.1).

Figure 92.1: Example of a full 360 degrees connection around the cable

93 Inside the enclosure cables can emit radiation which can then be amplified by the cavity of the enclosure, so it may be important to also shield the cables inside the enclosure. Tie-wraps and compressible cable-clamping strips can be helpful to make good connections with the conductive metal connector of the cable.

Fingerstrips

94 To pass on higher currents for entry plates and so on, a very good product is beryllium copper fingerstrips. Please note that not all countries accept these due to the percentage of beryllium which is toxic, therefore we have developed many other types of conductive gaskets. Which are more friendly for the environment and also less sensitive to damage. Another good solution is to place knitted mesh between the entry panel and the cage wall.

95 For screwed connections the 2400 series twisted fingerstrips are very popular. They can be compressed to the fingerstrips material thickness like 0.25 mm. Most versions can be sticked with a self-adhesive strip to keep the strip in place.

96 For shielded doors and Faraday cage doors you need a bigger range of compression. You find these in the 2800 series fingers can be clamped, soldered or screwed.

97 The 2100 series clip-on mounting Fingerstrips can be clamped on regular metal plate thicknesses like 0.5, 0.8, 1 and 1.5 mm. Some even have lances so that the strip will not slip loose quickly.

98 When there is a wide range of compression required, our 2200 series Snap-on Fingerstrips or our 2300 series Stick-on fingerstrips may be suitable. These fingerstrips with self-adhesive can be integrated in the construction.

Snap-on Fingerstrips can be firmly mounted in slots in your construction so that also a compression of nearly 0.25 can be realized. (fig. 98.1).

Figure 98.1: Snap-on fingerstrips for slot mounting and large compression

99 For special constructions, the 2500 series show fingers mounted under a 90-degree angle. (Fig. 99.1)

Figure 99.1: Example of technical drawing of finger under 90 degrees

100 For circular mounting the fingers in the 2600 series have spherical tips on top of the finger so that there is a good point contact for any angle.

101 For sliding, rotating and moving applications, please contact our specialists. To prevent wear down there is a conductive lubricant available.