- Contact Us

- |

- Jobs

- |

- About Us

- |

- |

-

- Personal information

- Organization

- Quotes

- Address book

- Login

- Don't have an account? Sign-up

Flexible EMI absorber sheets

- Home

- EMI & RFID absorbers, ferrites & pyramids

- Flexible EMI absorber sheets

The EMI flexible absorber sheets, developed for electromagnetic-wave absorption and noise suppression can eliminate noise effectively. EMC/EMI problems are solved by attaching noise-suppression sheets simply on the parts that are sources of noise.

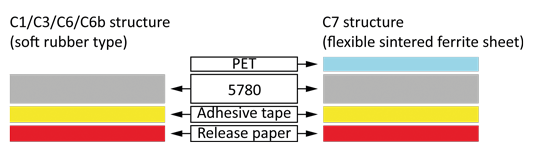

Material structure

Features and advantages

- Very flexible and easy to handle

- Can be delivered in any shape, size and/or thickness

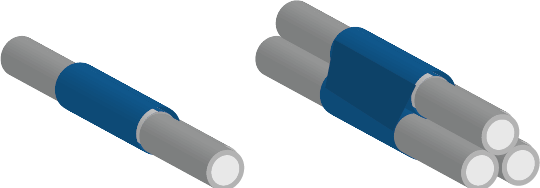

- Optionally available as a custom-made tube

- Can be cut according to the customer’s drawings

- Provides effective EMI suppression in a wide frequency range (1 MHz to 18 GHz)

- Changes the magnetic flux path to avoid interference with other components or surrounding cables

- Reduces the eddy current when the magnetic flux is close to metal

- Non-conductive adhesive backing (UL recognized) available

- Effective in preventing resonance and suppressing coupling

- High surface resistance (>10⁶ Ω)

- Easy and fast to process due to self-adhesive

Applications

- RFID (Radio Frequency Identification) systems

- NFC (Near-field communication)

- Wireless power chargers (WPC / Qi)

- Computers (NB / desktop / tablet) and peripherals

- Digital Products

- Mobile phones / smartphones / phablet

- Wireless equipment

- EMI-shielding box / black box

- Between printed circuit boards

- On IC’s, processors, and controllers

- On cables that need high flexibility

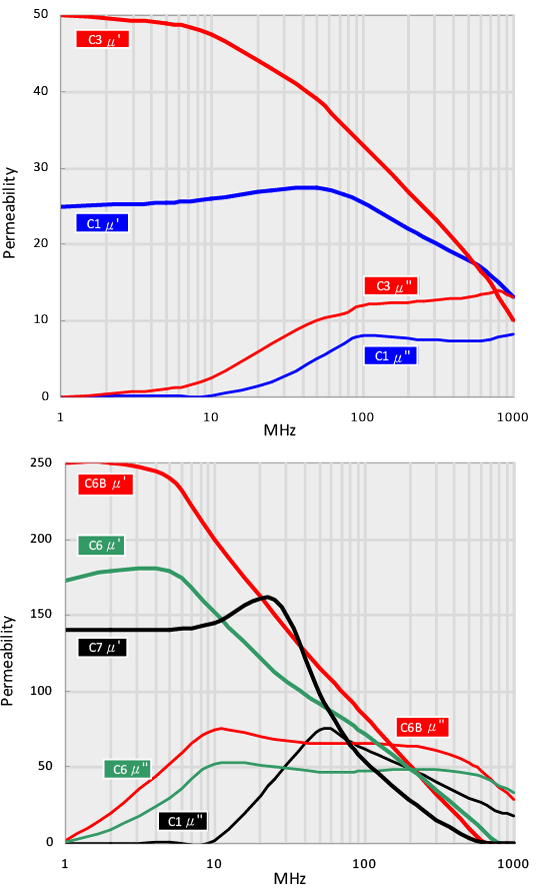

Choosing the right EMI flexible absorber sheet

| Item | C1 | C3 | C6 | C6b | C7 |

|---|---|---|---|---|---|

| Best Application | RFID, NFC | EMI, RFID, NFC | EMI, RFID, NFC, wireless charger (no magnet type) | EMI, RFID, NFC, wireless charger (no magnet type) | EMI, RFID, NFC, wireless charger (no magnet type) |

| Material | Magnetic powder + rubber | Magnetic powder + rubber | Magnetic powder + rubber | Magnetic powder + rubber | Sintered ferrite sheet |

| Acceptable frequency range | 1MHz - 18GHz | 1MHz - 18GHz | 1MHz - 9GHz | 1MHz - 9GHz | 1MHz - 3GHz |

| Operation temperature | -40 ~ +85 C° | -40 ~ +85 C° | -40 ~ +155 C° | -40 ~ +155 C° | -30 ~ +120 C° |

| Permability (µ'@1MHz | 25 | 50 | 170 | 250 | 140 |

| Density (g/cm3) | 3.6 | 4.8 | 3.8 | 3.8 | 3.8 |

| Surface Resistance (Ω) | 106 | 106 | 106 | 106 | 109 |

| RoHS 2.0 Compliance | 2011/65/EU | 2011/65/EU | 2011/65/EU | 2011/65/EU | 2011/65/EU |

| Halogen-Free | No | No | Yes | Yes | Yes |

| Thickness (mm) | 0.12/0.20/0.25/0.33/0.50/0.6/1.0/1.5/ 2.0/2.5 |

0.25/0.50/0.75 | 0.05/0.1/0.2/0.3/0.5 | 0.05/0.1 | 0.08/0.12/0.22 |

| Max. Dimension | 600 x 400 mm | 600 x 400 mm | 210 x 297 mm (A4) | 210 x 297 mm (A4) | 130 x 130 mm |

Application examples

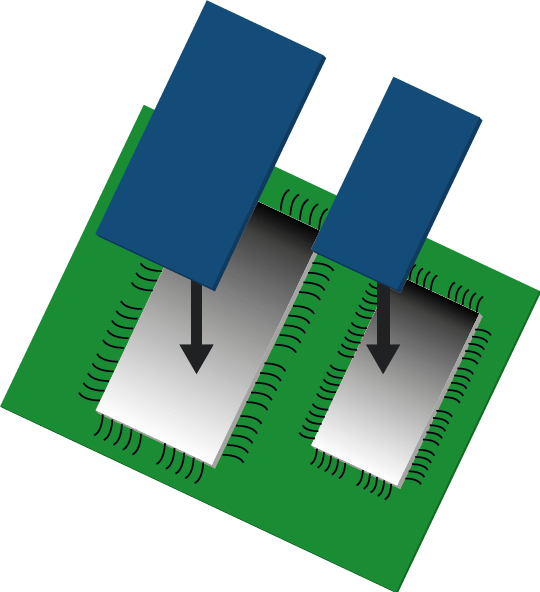

Example 1: Wrapped around a cable

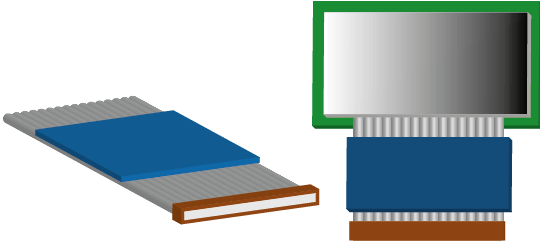

Example 2: Applied to a flat cable

Example 3: Applied to an integrated circuit (IC) top

Example 4: Applied between integrated circuits

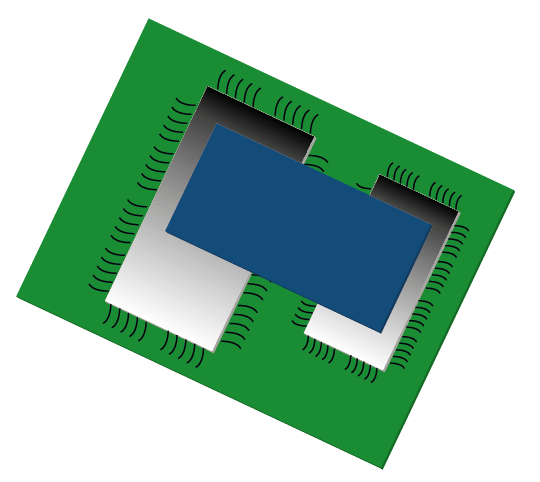

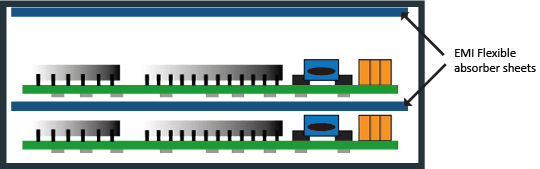

Example 5: Applied to case and between boards

Permeability ( µ = µ’ – j µ’’ )

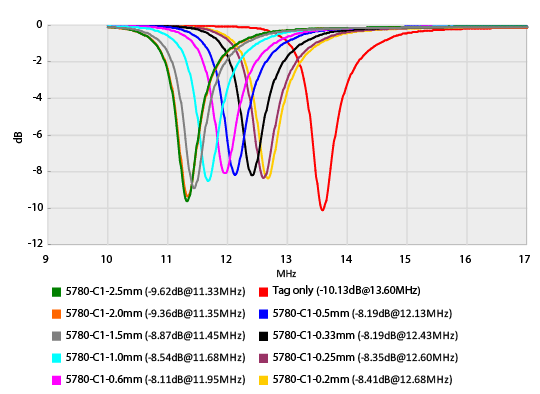

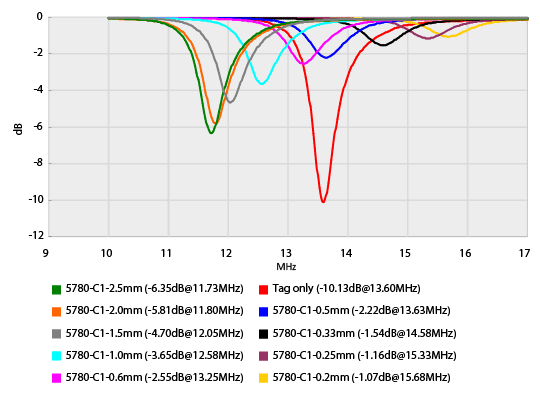

The variation of response frequency when RFID tag + 5780 + metal (Reference)

The response frequency is become lower when 5780 thickness become thick but the signal strength with little difference.

The response frequency is increase when metal attached, but the signal strength is smaller if the 5780 thickness is thinner. It means the metal affect more when the 5780 is thinner.

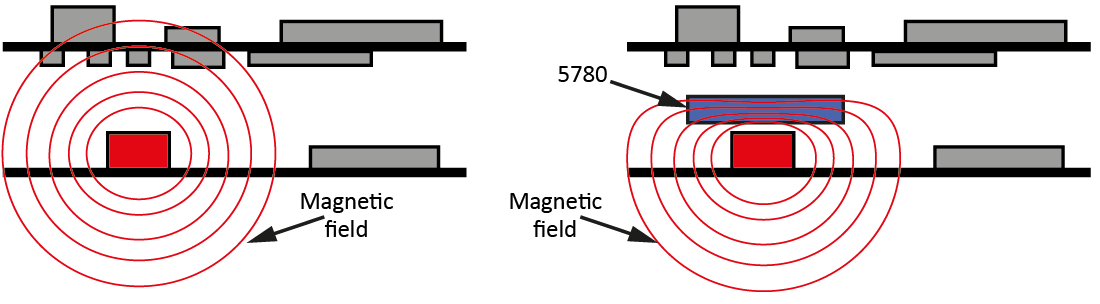

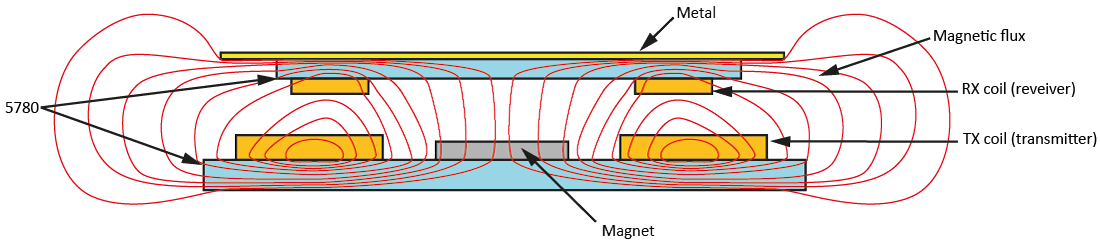

Effect diagram - Magnetic shield

5780 EMI flexible absorber sheets can change the magnetic flux path to keep the magnetic flux from affecting other components.

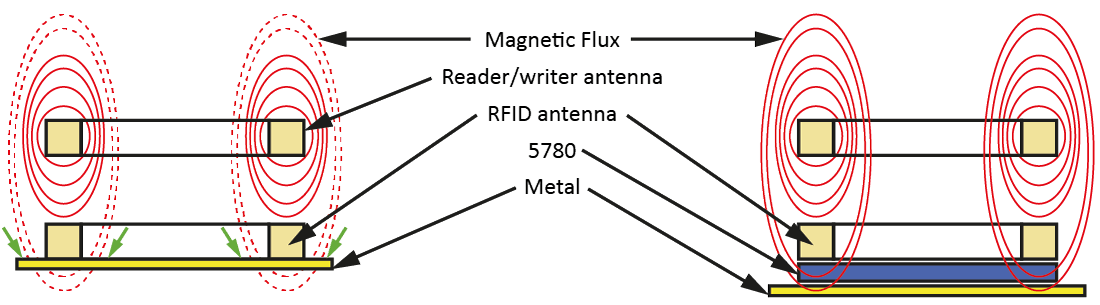

Effect diagram - RFID/NFC on metal

The magnetic flux induced an eddy current and generated a reverse magnetic field to offset the

magnetic flux to cancel the communication. After attaching an EMI absorber sheet between the metal and the RFID

antenna, the communication recovered.

Effect diagram - Wireless power charger

5780 EMI Flexible absorber sheets can be used for a wireless power charger to avoid eddy current when the RX coil is attached to metal; this changes the magnetic flux path between TX coil, RX coil, and magnet.

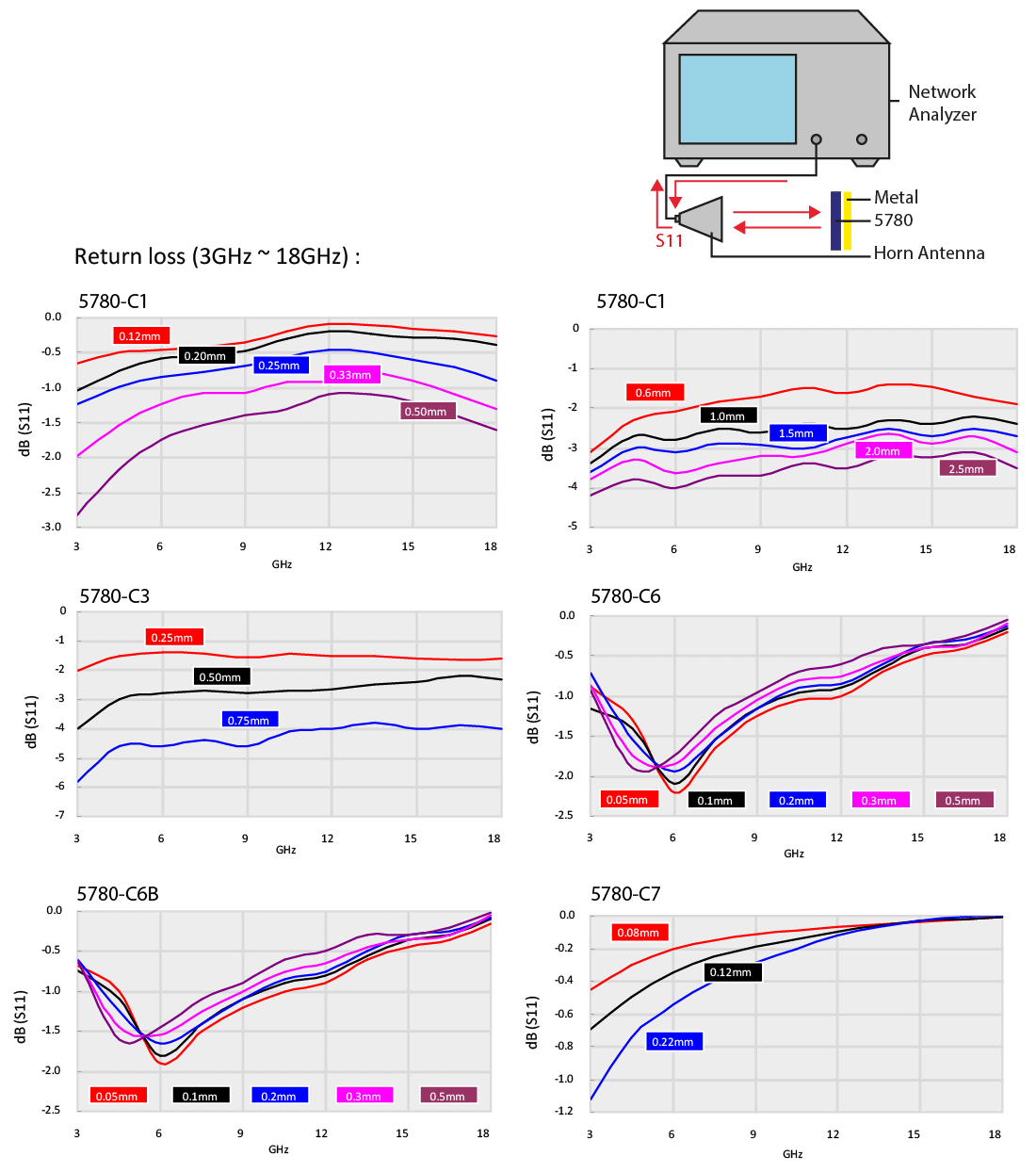

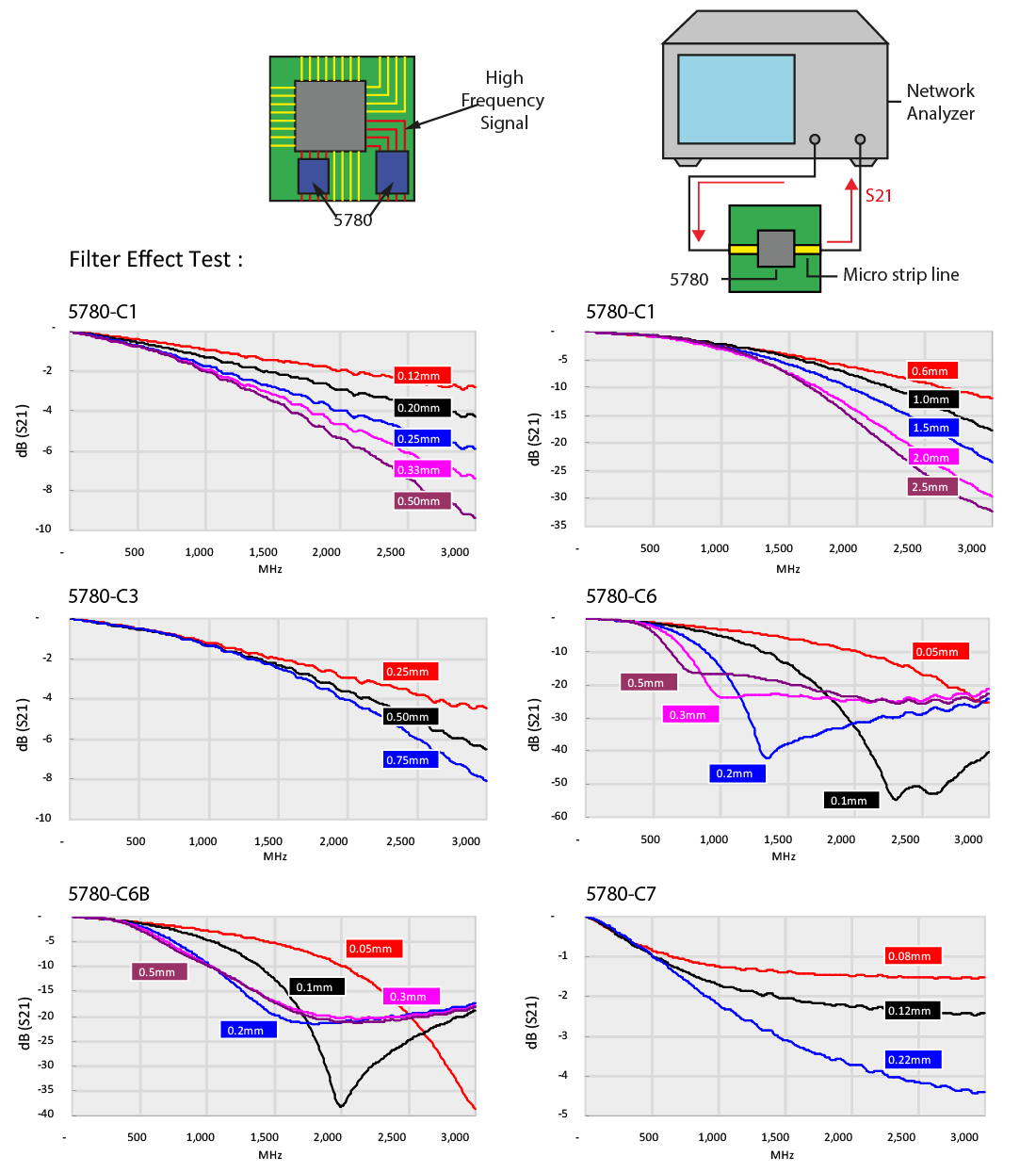

Filter Effect Test

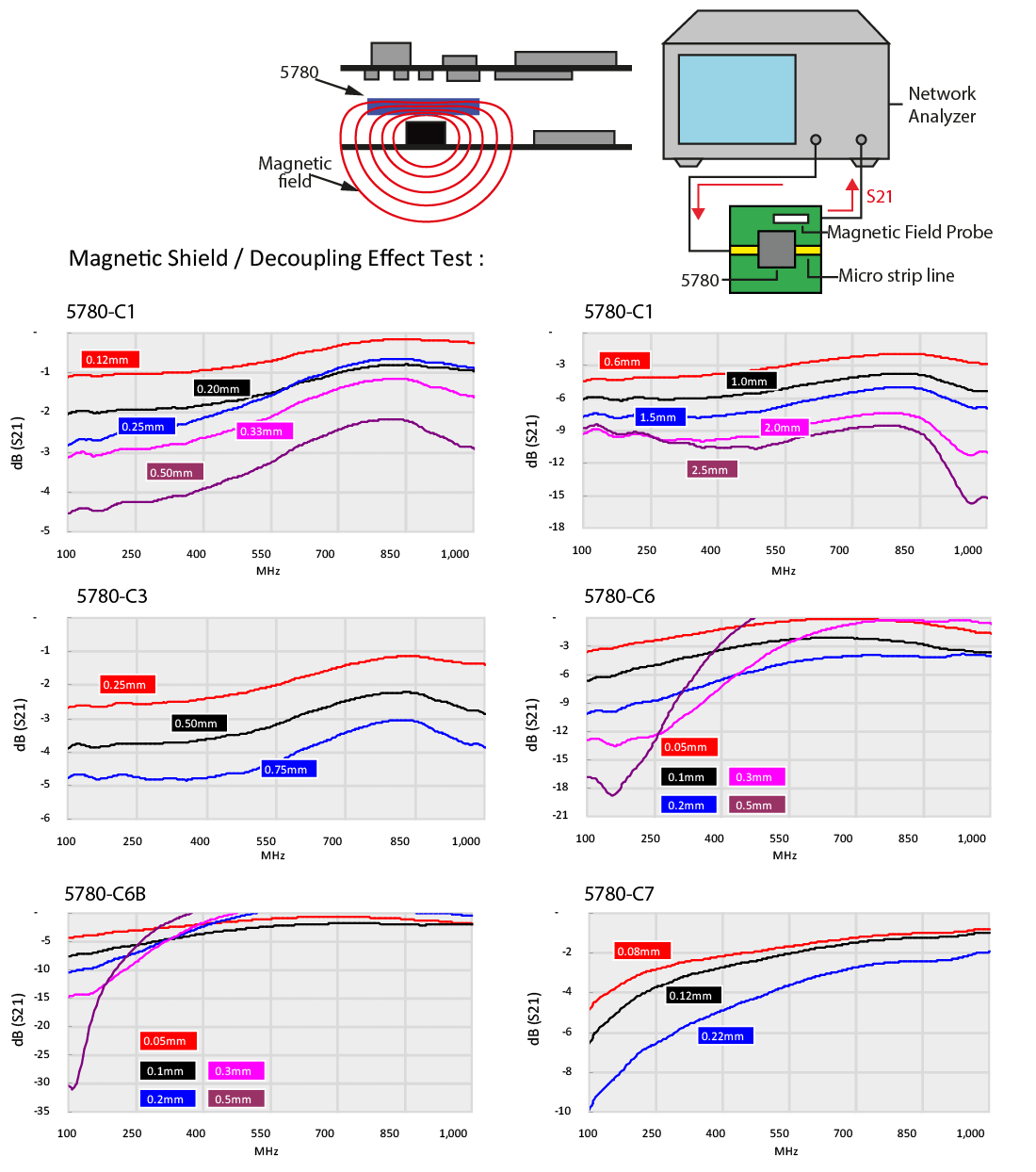

Magnetic Shield / Decoupling Effect Test

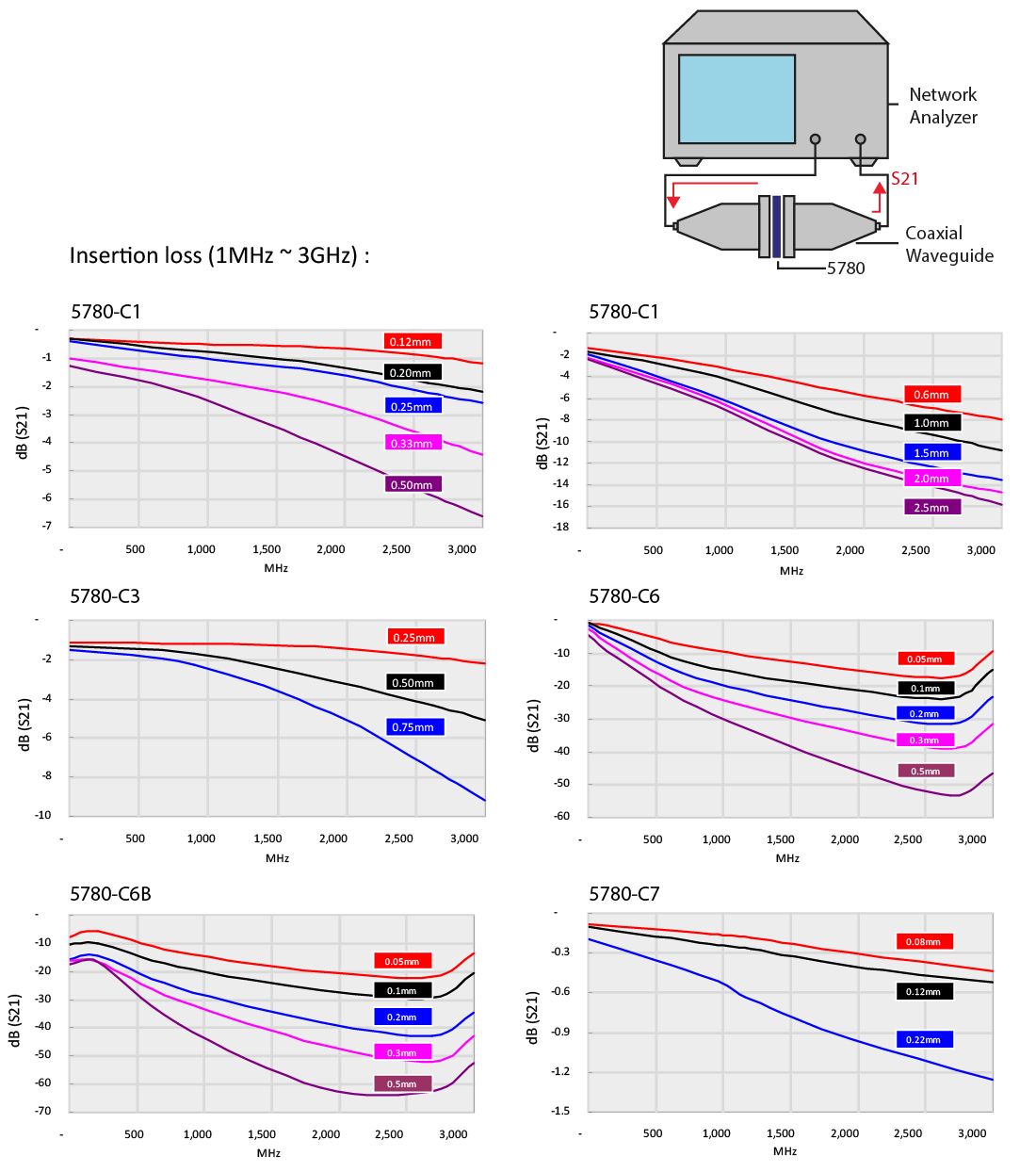

Insertion loss (1MHz ~ 3GHz)

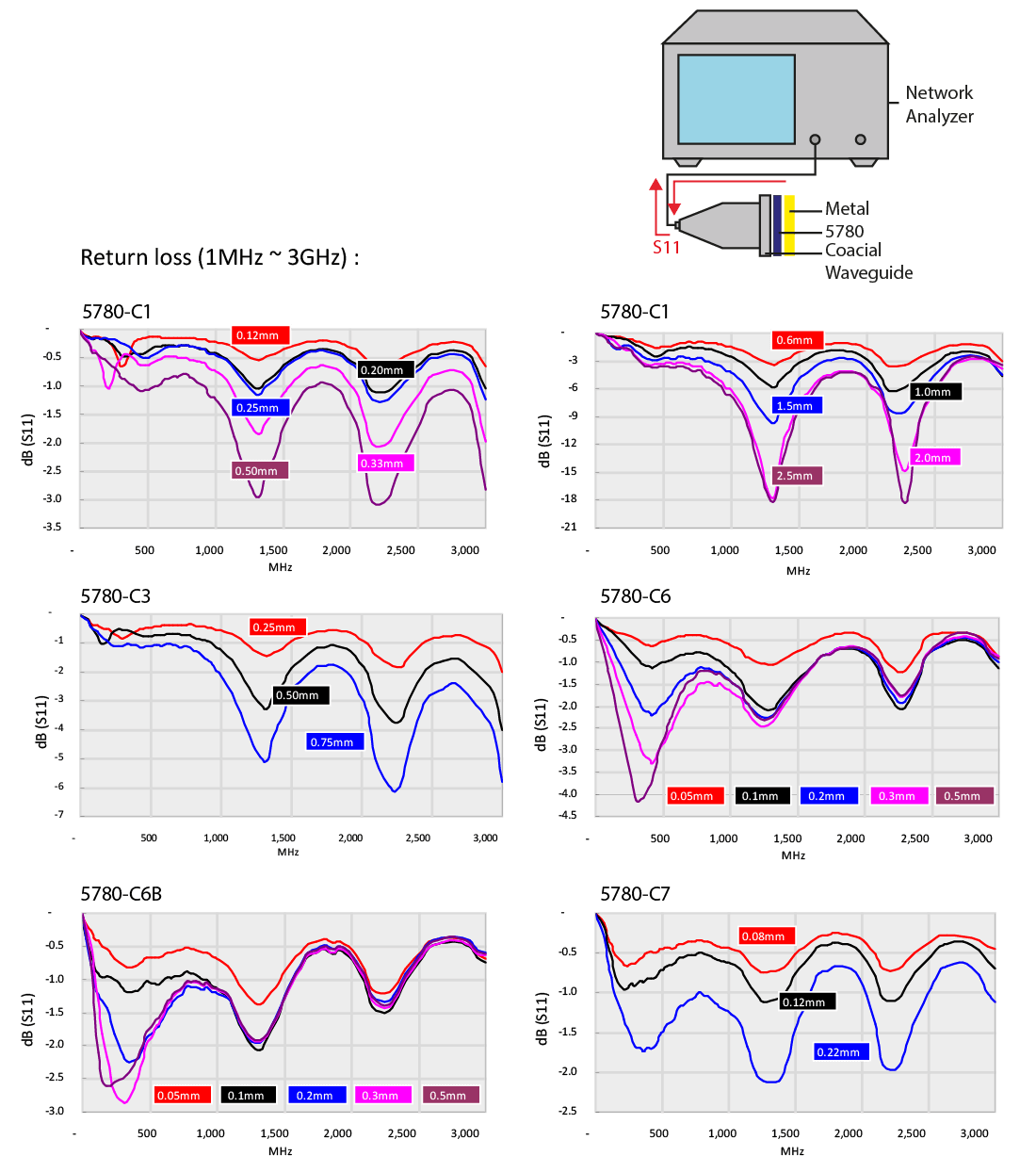

Return loss (1MHz ~ 3GHz)

Return loss (3GHz ~ 18GHz)