- Contact Us

- |

- Jobs

- |

- About Us

- |

- |

-

- Personal information

- Organization

- Quotes

- Address book

- Login

- Don't have an account? Sign-up

EMI cable-shielding tie-wrap

- Home

- EMI shielding cables & entries

- EMI cable-shielding tie-wrap

For process measurement and control equipment an increasingly higher level of protection against failure is required. EMI shielding and earthing are very important. The area where the cable shield is connected to the cabinet earth is a critical point. It is very important that the connection has a low resistance.

We provide a tie-wrap solution that is very easy to install, since no tools are required. The tie-wrap is made of plastic and the electrically conducting layer is made of a springy metal wire mesh which is pulled together easily by tightening the tie-wrap.

EMI cable-shielding tie-wrap provides a highly effective shield termination for any size and type of backshell design. EMI cable-shielding tie-wrap has successfully passed rigorous testing with respect to shocks, vibrations and thermal cycles unlike other shield-termination systems. There is no device on the market that realizes shield termination more quickly.

EMI cable-shielding tie-wrap provides a quick and reliable way of terminating cable shielding for critical applications in aircraft, military vehicles and other sensitive electronic equipment.

Our EMI cable-shielding tie-wrap can also be used as an EMC cable clamps for mounting on for example bus bars.

Benefits

To protect sensitive equipment, EMI cable-shielding tie-wrap is designed to provide the following advantages:

- Virtually eliminates RFI/EMI/EMP-leakage paths

- Maintains constant tension under extreme environmental conditions

- Clasps small diameters just as easily, quickly and reliably as large diameters

- Simple and tool-free assembly

- Save space by an optimized arrangement

- Permanent and continuous pressure on the cable shield, adjustment of spring load not necessary

- Vibration proof, maintenance free

Knitted mesh specifications

| Material | Applications |

|---|---|

| Monel Per QQ-N-281 BS 3075 N A 13 Class A |

The most commonly used material. Insensitive to corrosion and neutral on the galvanic scale. |

* On request it is possible to use a different knitted wire mesh cover.

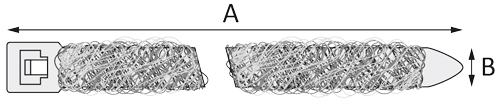

Standard sizes

| Part number | Width B (mm) | Length A (mm) | |

|---|---|---|---|

| 4950-25100 | 2.5 | 100 | |

| 4950-25160 | 2.5 | 160 | |

| 4950-25200 | 2.5 | 200 | |

| 4950-36100 | 3.6 | 100 | |

| 4950-36140 | 3.6 | 140 | |

| 4950-36200 | 3.6 | 200 | |

| 4950-36300 | 3.6 | 300 | |

| 4950-36370 | 3.6 | 370 | |

| 4950-48200 | 4.8 | 200 | |

| 4950-48250 | 4.8 | 250 | |

| 4950-48300 | 4.8 | 300 | |

| 4950-48370 | 4.8 | 370 | |

| 4950-48430 | 4.8 | 430 | |

| 4950-76200 | 7.6 | 200 | |

| 4950-76370 | 7.6 | 370 | |

| 4950-76450 | 7.6 | 450 | |

| 4950-13290 | 13 | 290 |

Notice: tie-wrap dimensions are without mesh material.

Mesh material is 0.2 mm. For example: a tie-wrap of 3.6 mm the total thickness with mesh is 4 mm.

* On request, many other dimensions can be manufactured.