- Contact Us

- |

- Jobs

- |

- About Us

- |

- |

-

- Personal information

- Organization

- Quotes

- Address book

- Login

- Don't have an account? Sign-up

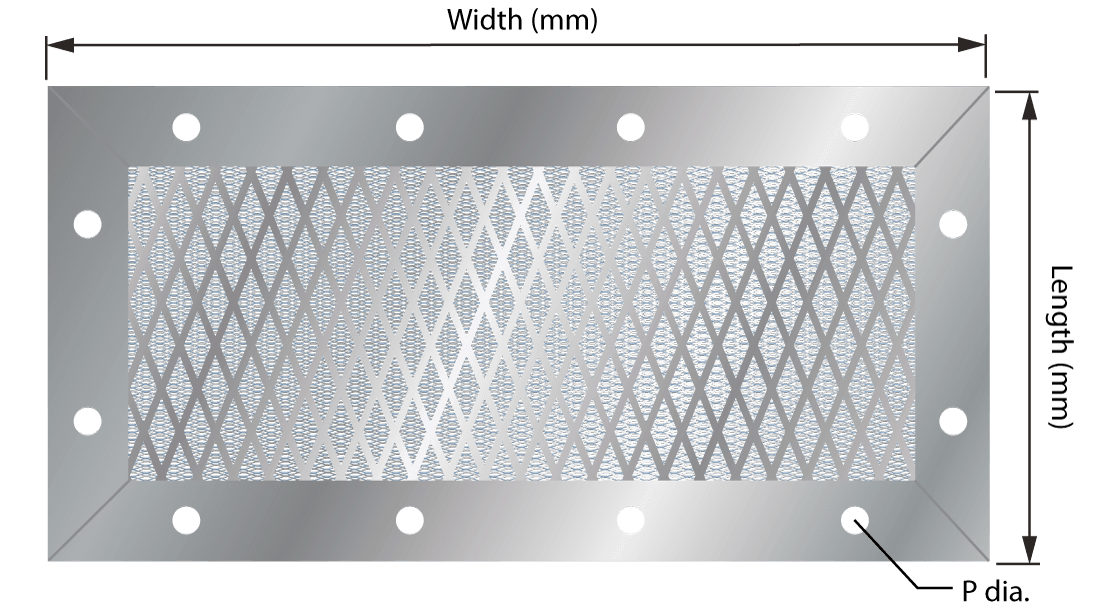

EMC woven mesh ventilation panel

- Home

- EMI - EMP ventilation and dust panels

- EMC woven mesh ventilation panel

EMC Woven mesh ventilation panels are used for heating, air flow for cooling and ventilation in electronic enclosures without compromising the shielding integrity of an enclosure.

Aluminium EMC Woven mesh ventilation panels consist of 3 layers of pleated Aluminium woven mesh, trapped between Aluminium kick-plates, in a rigid Aluminium frame, pre-drilled or with fasteners made to your specifications or flow drilled thread holes.

The 3 layers of pleated wire mesh are separated by the pleats being of different height, thus enabling the vent to have a high dust holding capacity.

Approximately 95% of the 9520 series EMC Woven mesh ventilation panels are made to customer specifications, and are all made to comply an order. Custom finish on request.

These panels can be treated with a variety of finishes to provide corrosion protection or improve conductivity. Air filter oil can be applied to the Aluminium filter media to assist in dirt and dust retention. Panels with a gasket groove have a knitted monel wire mesh gasket as standard. Other frames can be provided with an additional EMI Gasket.

Please note : These values are measured under laboratory conditions. Results may vary in other situations; please read our Guarantee.

Options (on request)

- EMI gasketing

- Environmental sealing

- Kempass (RoHS) Aluminium passivation finish

Benefits

- Light weight

- High shielding performance

- Very low air-flow resistance

- Reduction of turbulence

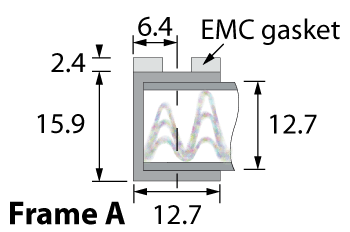

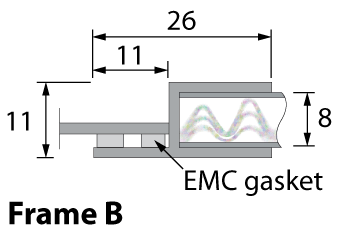

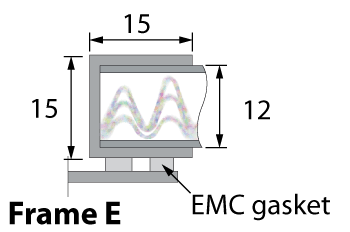

EMC gasket options

- 6800 series Amucor shielding gasket

- 1200 series Knitted wire mesh gasket

- 5770 series Electrically conductive foam

* Other gasket options on request

Design and constructional tips

In your design, you can take into consideration moisture and dust protection through:

- Color coated frame (leave a part free of coating for contact)

- External overhang for rain protection

- Holes for drainage

- Aerodynamic drag

- Additional EMC gasketing

- Try to avoid round vents because of their complexity and therefore expensive production

- Prevent holes in corners of the frame because of the rigidity of the frame when compressing the gasket

- If specifying captive inserts in both sides of the frame off-set the position by 10 mm minimum

Attenuation levels (dB)

| Frequency | dB |

|---|---|

| 0.01 MHz | 42 |

| 0.1 MHz | 53 |

| 1.0 MHz | 61 |

| 10.0 MHz | 81 |

| 100 MHz | 60 |

| 1000 MHz | 52 |

| 10000 MHz | 43 |

Frame options

Technical drawing