- Contact Us

- |

- Jobs

- |

- About Us

- |

- |

-

- Personal information

- Organization

- Quotes

- Address book

- Login

- Don't have an account? Sign-up

Electrically conductive adhesive (Shieldokit)

- Home

- EMI coatings, conductive glues, thermal, lubricants and seals

- Conductive glue

- Electrically conductive adhesive (Shieldokit)

Shieldokit creates an electrically and thermally conductive connection between components (electrically conductive adhesive). One of the applications is EMI shielding. The conductive glue cures at room temperature and has excellent filling properties. This conductive glue can be used to fill uneven surfaces because of its viscosity, which is comparable to peanut butter.

The product consists of a two-component epoxy-based glue containing 65% silver. It is a paste which can be applied to metals (copper, aluminium, stainless steel, brass, etc.), ceramics and most plastics.

Structure

Shieldokit is a solvent-free, silver pigmented adhesive, based on a two-component epoxy resin.

Special characteristics

The kit creates a strong connection with excellent conductivity. It is designed to connect temperature-sensitive components.

| Part number | Description | |

|---|---|---|

| 3980-14 gram | Electrically conductive adhesive (Shieldokit) 14 gram |

Application

Shieldokit is designed to connect parts at temperatures between 20 °C and 80 °C. The adhesive can be applied with a dispenser or by screen printing. Tools have to be cleaned immediately after use.

Used for:

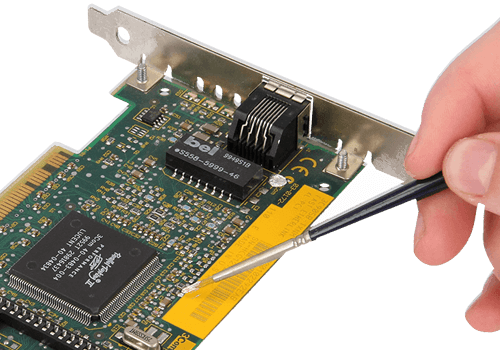

- Gluing components that cannot be soldered

- Connections that require excellent electrical conductivity

- Connections that have to be thermally conductive

- Repairing non-solderable components

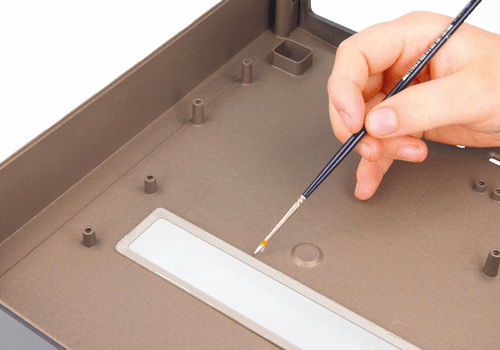

- Gluing objects to a plastic enclosure where an electrically conductive linkage is needed

- Restoration of flat cables, SMD components, etc.

Cure instructions

The product will cure at room temperature for 24 hours or cure the adhesive in a oven at one of these time/temperature options:

15 min @ 65 ˚C

7 min @ 125 ˚C

Electrically and thermally conductive connection between heat-sensitive components that cannot be soldered

The glue can be used for creating a conductive edge for convenient mounting

Electrically conductive connection between a conductive window and a plastic enclosure, ensuring full EMI-shielding integrity

Cured properties

| Resistivity | 7.0 x 10-3 Ω·cm |

|---|---|

| Hardness | 73 D |

| Tensile Strength | 13 N/mm2 |

| Compressive Strength | 39 N/mm2 |

| Lap Shear (stainless steel) (aluminum) |

3.8 N/mm2 5.5 N/mm2 |

| Water Absorption | 0.04 % |

| Outgassing @ 125 ˚C for 24 h | 6.3 % |

| Glass Transition Temperature (Tg) | 50 ˚C |

| CTE Prior Tg | 54 ppm/˚C |

| CTE After Tg | 169 ppm/˚C |

| Thermal Conductivity @ 25 ˚C | 1.4 W/(m·K) |

| Service Temperature Range | -55–150 ˚C |

Usage Parameters

| Working Time | 10 min |

|---|---|

| Service Cure | 5 h @ 22 ˚C |

| Mix Ratio by Volume | 1:1 |

| Mix Ratio by Weight | 1.04:1 |

Uncured Properties

| Mixed Density | 2.29 g/mL |

|---|---|

| Shelf Life | 2 years after production date |

| Viscosity @ 25 ˚C | (A) 1.000 Pa·s (B) 15.000 Pa·s |