- Contact Us

- |

- Jobs

- |

- About Us

- |

- |

-

- Personal information

- Organization

- Quotes

- Address book

- Login

- Don't have an account? Sign-up

Conductive rubber PCB shielding gasket

- Home

- PCB shielding

- PCB shielding gaskets

- Conductive rubber PCB shielding gasket

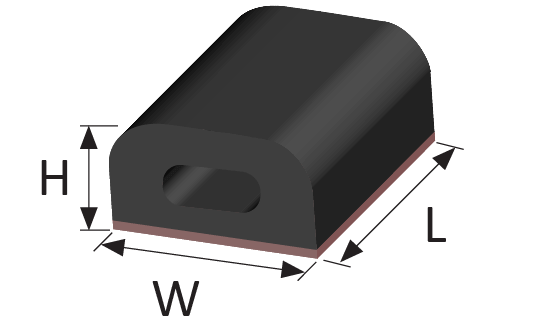

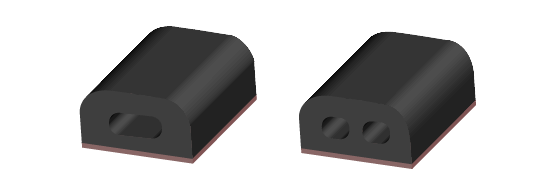

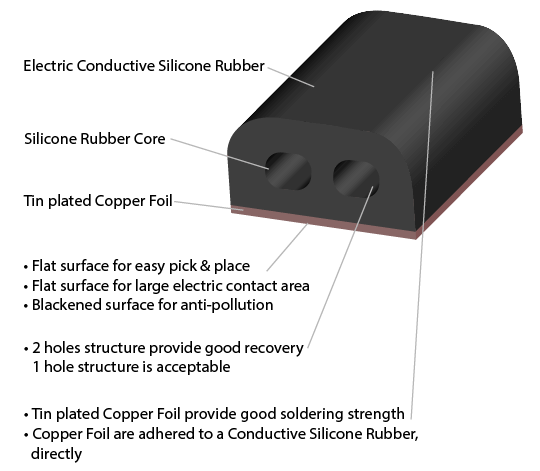

1560 series is Surface Mountable Technology (SMT) compatible electric elastomer connector. The shielding gasket has good elastic recovery and electric property, so it offers not only cushion, but also electrical connecting and grounding between electrical objects and PCB. The 1560 series consist of a conductive coating layer on an elastomer tube and a solderable metal foil under the tube. So it has good electrical conductivity and better soldering strength.

Standard part numbers

| Part number | Dimensions (mm) | ||

|---|---|---|---|

| W | H | L | |

| 1560-200810 | 2.0 | 0.8 | 1.0 |

| 1560-201110 | 2.0 | 1.1 | 1.0 |

| 1560-201310 | 2.0 | 1.3 | 1.0 |

| 1560-201410 | 2.0 | 1.4 | 1.0 |

| 1560-201615 | 2.0 | 1.6 | 1.5 |

| 1560-201815 | 2.0 | 1.8 | 1.5 |

| 1560-202015 | 2.0 | 2.0 | 1.5 |

| 1560-202518 | 2.0 | 2.5 | 1.8 |

Main characteristics

- Low electric resistance

- Passes most salt spray and environmental tests

- Good resilient & recovery property. Easy to apply SMT and repair.

- Strong soldering strength and not easy to detach on PCB

Applications

- Smart phone

- Mobile device

- Tablet

- PC

- LCD Panel, navigation for electric connecting and grounding.

Properties

| Product Type | 1560 series | ||

|---|---|---|---|

| Colour of Conductive Coating Layer | Black | ||

| Width | 2.0mm ~ | ||

| Height | 0.8mm ~ | ||

| Compression ratio | Typical 10% ~ 40% compression of original height | ||

| Operation temperature | -35 °C ~ 160 °C | ||

| Resistance | Vertical | Typical 0.05 Ω | |

| Surface | Typical 0.05 Ω/□ | ||

| Soldering strength | Length direction | Not easy to detach & removal due to flexibility & shove |

Typical 150 gf for 1560-2.0-1.1-1.0 |

| Width direction | Typical 200 gf for 1560-2.0-1.1-1.0 | ||

| Elastomer Hardness | Shore A 50 | ||

| Recovery rate (30%×10.000 times) |

Typical 93 % | ||

| Abrasion Test | No metal dust after rubbing with PP tape (2 kg Roller / 10 cycles) | ||

| Thermal Shock | Change ratio of resistance & elasticity is lower than 10% (-40 °C × 0.5 hr ↔ 85 °C × 0.5 hr × 100 cycles) | ||

| High Temperature/Humidity | Change ratio of resistance & elasticity is lower than 10% (85 °C / 85% RH / 100 hrs) | ||

| Salt Spray | No changing of color and electric resistance (KS D 9502, 5% NaCl, 35 °C / 48 hrs) | ||

| Flammability | Classified by UL to UL 94 V-1 | ||

| Environment | Halogen Free, EU-RoHS Compliant, Lead Free | ||

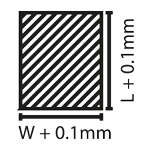

| Recommend Solder Pattern (Separated Pattern) |

solder pattern and the 100 µm thickness of solder cream |

||

| These values are measured under laboratory conditions. In other situations results may differ. Please read our Guarantee. |

|||

Alternatives

Alternatives for PCB shielding gaskets are PCB spring contact fingers series.. PCB fingers are made of metal and therefore have better conductivity and are therefore suitable for applications where high currents flow. These PCB contact fingers come in many shapes and sizes.

Structure & features

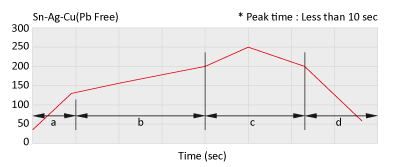

Recommended re-flow soldering condition for SN plating

| Condition of re-flow soldering (Recommended) | ||

|---|---|---|

| Zone | Temperature (deg. °C) | Time (sec) |

| A | RT ~ 130 | 60 |

| B | Max. 220 | 90 ~ 150 |

| C | 220 ~ 250 (max. 250) | 90 ~ 150 |

| D | 220 ~ RT | Min. 60 |